I do a lot of work with electrical junction boxes, and always need to drill holes for conduit connectors. It’s always a PITA, the boxes are too flexible to stand up in the drill press. So the holes tend to drift from the intended location. And my various sheet metal punches usually don’t have enough throat depth to reach.

So I’m thinking of fabricating a new table for my drill press, with a triangular table. This way I could hang the junction box off the table from the junction box side that I am drilling.

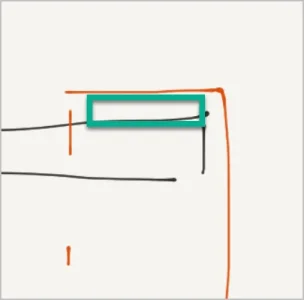

Kind of like cutting back the table as the red hatch marks on the photo. My thumbnail sketch of how the junction box (red) could hang off the drill press table (black)?

Any thought on this? Anyone else run into this problem?

So I’m thinking of fabricating a new table for my drill press, with a triangular table. This way I could hang the junction box off the table from the junction box side that I am drilling.

Kind of like cutting back the table as the red hatch marks on the photo. My thumbnail sketch of how the junction box (red) could hang off the drill press table (black)?

Any thought on this? Anyone else run into this problem?