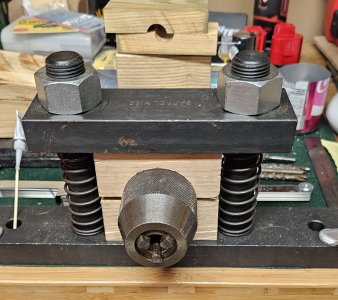

I recently bought a Golden Goose 3/4in ball bearing chuck and an Albrecht 5/8 keyless chuck on Kijiji.

The golden goose came without the key - dummy me forgot to ask.

The Albrecht came with scored jaws and a gummy feel.

I orded a 5 key set on Amazon. The biggest was too small. Crap. That meant spending some serious money.....

MCMaster Carr has a huge selection. I went through them one by one looking for one with a 3/8ths pin. They had one just under that. It was PN 3169A16 at $14.31 us.

The Jaws for the Albrecht were $188us but a new chuck is $760 US. I ordered the Jaws and a set of bearing balls.

Everything shipped free from the USA AND ARRIVED THE NEXT DAY!!! WOW!

The key fit perfect! Very happy!

The jaws look to be the right size but I won't know till after I figure out how to get the chuck apart.

The golden goose came without the key - dummy me forgot to ask.

The Albrecht came with scored jaws and a gummy feel.

I orded a 5 key set on Amazon. The biggest was too small. Crap. That meant spending some serious money.....

MCMaster Carr has a huge selection. I went through them one by one looking for one with a 3/8ths pin. They had one just under that. It was PN 3169A16 at $14.31 us.

The Jaws for the Albrecht were $188us but a new chuck is $760 US. I ordered the Jaws and a set of bearing balls.

Everything shipped free from the USA AND ARRIVED THE NEXT DAY!!! WOW!

The key fit perfect! Very happy!

The jaws look to be the right size but I won't know till after I figure out how to get the chuck apart.