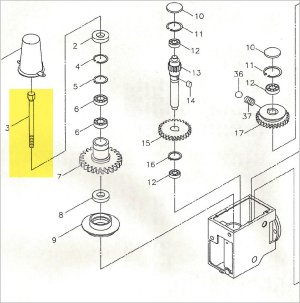

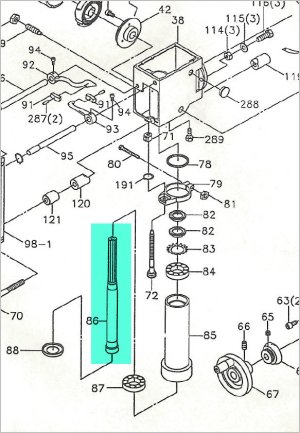

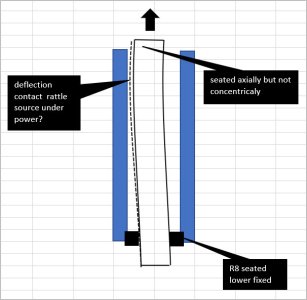

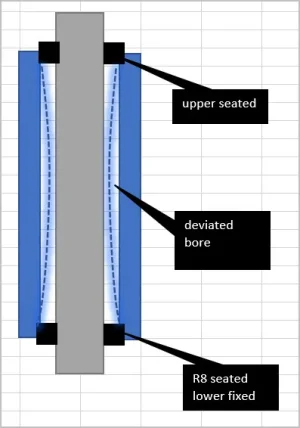

I've been annoyed at how the draw bar seems to rattle around on both my mills (Hartford & Bridgeport). It's fine at the business end where it screws into an R8 tool holder. However, the top of the draw fits too loosely into the top of the spindle.

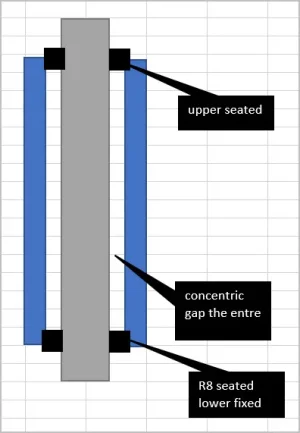

Here is my fix. Super easy to do. Rattle is gone.

The root of the problem is that the Drawbar is a 7/16 bar with 7/16-20 "ROLLED" threads on it. Because the threads are rolled, they are a bit bigger than the drawbar shaft. Therefore any regular bushing slipped over the threads ends up loose on the shaft.

The spindle ID is 0.512 on both mills. A custom fit nose goes into the spindle shaft and guarantees that the shaft is centered at the top of the spindle too.

The trick is to cut shallow threads so the thread ID on the collar is the same as the Drawbar shaft, but the threads on the shaft still pass through such that the assembled collar fits the shaft after is screwed on over the end threads.

Easy satisfying project. Hope it helps someone else.

Here is my fix. Super easy to do. Rattle is gone.

The root of the problem is that the Drawbar is a 7/16 bar with 7/16-20 "ROLLED" threads on it. Because the threads are rolled, they are a bit bigger than the drawbar shaft. Therefore any regular bushing slipped over the threads ends up loose on the shaft.

The spindle ID is 0.512 on both mills. A custom fit nose goes into the spindle shaft and guarantees that the shaft is centered at the top of the spindle too.

The trick is to cut shallow threads so the thread ID on the collar is the same as the Drawbar shaft, but the threads on the shaft still pass through such that the assembled collar fits the shaft after is screwed on over the end threads.

Easy satisfying project. Hope it helps someone else.

Last edited: