deleted_user

Super User

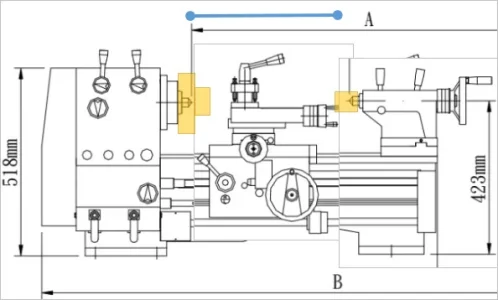

In my research of Taiwanese manufacturers I discovered something I did not realise even existed. The 12x16 metal lathe.

Until now I'd only thought that 10" lathes in the 18-22" length existed in this footprint... and I've often considered purchasing a 10x18 or 10x22 but just can never bring myself to pull the trigger on one because of the throw limitations and weight.

A 12x16" lathe I could actually squeeze into my tiny basement shop. My question is, are they too light, are they as well made as a 12x36 lathe? Does anyone here have experience with one of this size of lathe?

Why do people think that busybee does not offer this size lathe?

Until now I'd only thought that 10" lathes in the 18-22" length existed in this footprint... and I've often considered purchasing a 10x18 or 10x22 but just can never bring myself to pull the trigger on one because of the throw limitations and weight.

A 12x16" lathe I could actually squeeze into my tiny basement shop. My question is, are they too light, are they as well made as a 12x36 lathe? Does anyone here have experience with one of this size of lathe?

Why do people think that busybee does not offer this size lathe?