dave_lawson@

Active Member

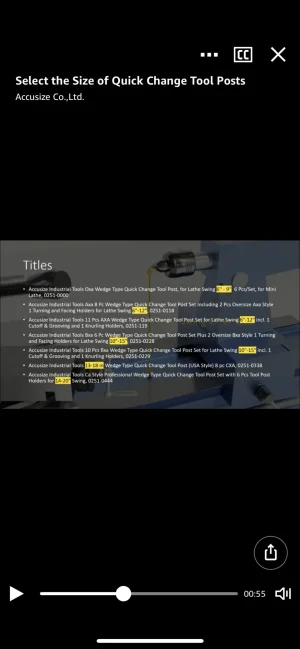

Trying to figure out which unit to buy for the quick change toolpost on the Busy Bee CX709. No response from their customer service and calling the store seems to be a waste of my time.

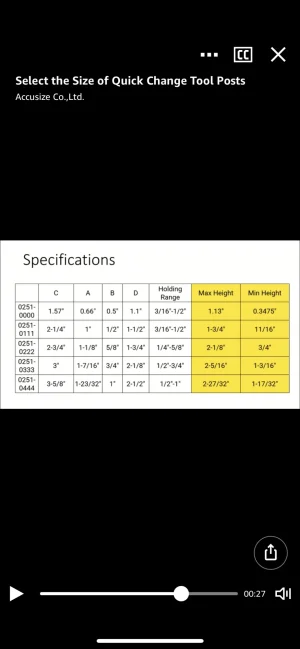

Anyone know if the Accusize BXA model will fit this model of lathe? Alternately, some other well known model either from Busy Bee themselves (their website does not describe which of their lathes are compatible, nor does the lathe indicate which to choose).

I can see one reference online to the CX709 (13x24) that looks like the BXA model, but I can't quite make it out to be certain.

Thank for anyone who can help me - especially those who have been through this with a CX709 themselves.

Anyone know if the Accusize BXA model will fit this model of lathe? Alternately, some other well known model either from Busy Bee themselves (their website does not describe which of their lathes are compatible, nor does the lathe indicate which to choose).

I can see one reference online to the CX709 (13x24) that looks like the BXA model, but I can't quite make it out to be certain.

Thank for anyone who can help me - especially those who have been through this with a CX709 themselves.

Last edited by a moderator: