Since being a Tool maker for close to 35 years with no real lathe experience, other than turning bumpers and the odd broken punch or bushing in a pinch. My experience was pretty much nil...

The lathe certainly was a learning curve. I'd be lying if I said I wasn't scared myself when going through the learning process.

Was using coolant for everything at the time with the lathe and was difficult to see my distance to go before nailing the jaws haha.

I must say, the window is tough, the hub I was doing didn't come through it, spinning it at 3700rpm. Didn't take long to spit it out that's for sure.

Since, I was up close to that window watching my distance to go I figured I got lucky. I didn't have to shell out another 5k for new dentures.

luckily, I only had to change my underware and pluck a few more grey hairs out. Probably why I'm mostly grey now haha.

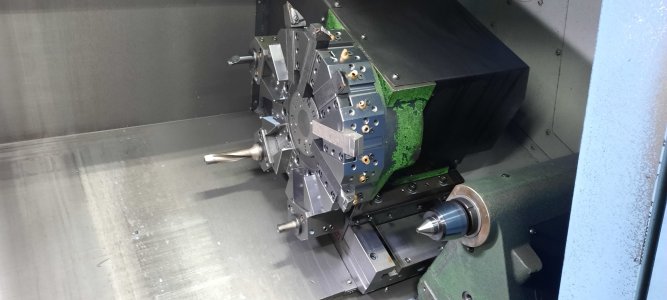

The 2 axis lathe suits me just fine these days. I'm still light years behind the live tooling, C&Y axis lathes. I load each part, no bar feed yet and I still encounter problems haha.

I hope your enjoying the trade Dan, I've had many good years over the years. Enjoy it!