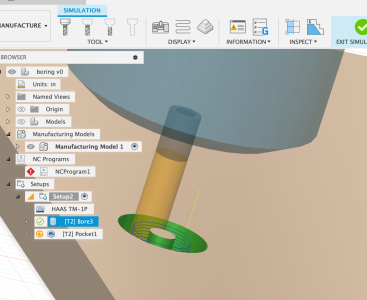

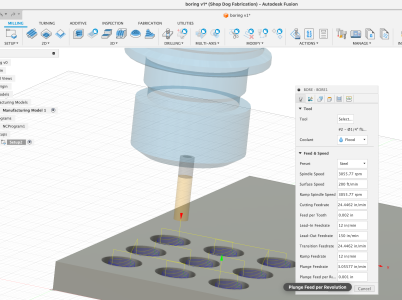

Creating this and the CAM that went with it was amazingly easy and fast with AlibreCAD/CAM. A friend tried it in Fusion360 and apparently a milled pocket has to have a bottom or it's not a pocket. In AlibreCAM (MecSoftCAM) a pocket has diameter and depth and based on the endmill and rpm the path is circular with a specific depth until the depth is reached. If the depth is larger than the model thickness Fusion360 complains and won't make the pocket.

I whipped up a quick model in Alibre. Easy Peasy. Is it actually easy in Fusion360 and he's just gone down the wrong path?

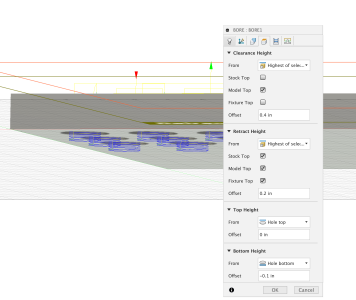

Side view of the mill path showing a pocket milled deeper than the material.

I whipped up a quick model in Alibre. Easy Peasy. Is it actually easy in Fusion360 and he's just gone down the wrong path?

Side view of the mill path showing a pocket milled deeper than the material.

Last edited: