Max Simons

Member

Hi Guys,

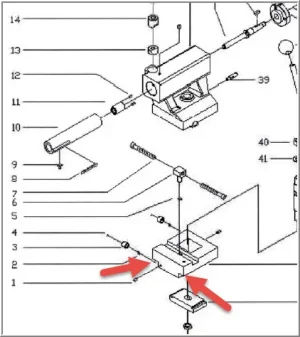

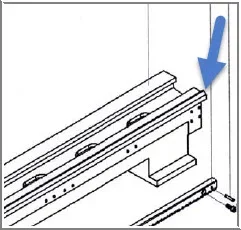

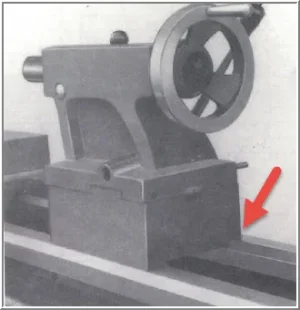

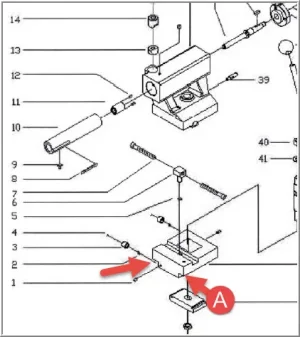

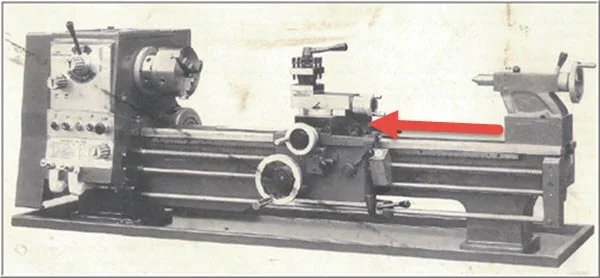

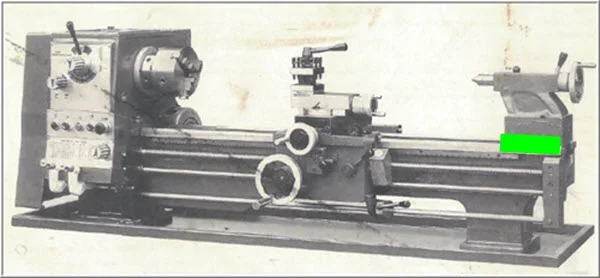

I have the Craftex CT089 13x24" metal lathe from busy bee. Im having a few issues. Firstly, the tailstock doesn't seem to want to center properly. It has an adjustment on it to move it in our out, but the issue i have it that it kind of "twists" on the bed when you apply the cam lock. The other issue is that the head stock seems to have alot of "Ballslap" and it quite noisy. When i run it at any speed over 450rpm, the chuck kind of "chatters" like its out of balance or something. I have read that some guys replace all the chinese bearings with good quality ones and this is supposed to help quite a bit. Has anybody ever attempted this? Maybe my expectations are just too high for a chinese machine.....?

I have the Craftex CT089 13x24" metal lathe from busy bee. Im having a few issues. Firstly, the tailstock doesn't seem to want to center properly. It has an adjustment on it to move it in our out, but the issue i have it that it kind of "twists" on the bed when you apply the cam lock. The other issue is that the head stock seems to have alot of "Ballslap" and it quite noisy. When i run it at any speed over 450rpm, the chuck kind of "chatters" like its out of balance or something. I have read that some guys replace all the chinese bearings with good quality ones and this is supposed to help quite a bit. Has anybody ever attempted this? Maybe my expectations are just too high for a chinese machine.....?