Ever since I purchased my air compressor it’s had a slow leak, but since it was either under a bench or in a corner I never looked to see what the cause was, naively assuming it was just one of the fittings needed re-sealing… until today…

It probably has only 100 to 200 hours of running spread over 20 years, with the air tank drained after each use.

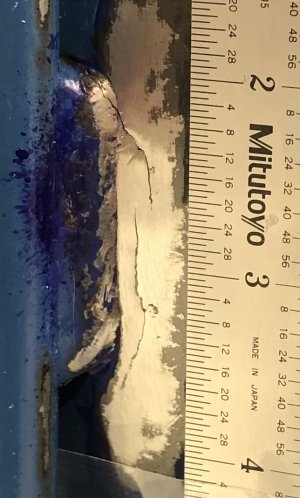

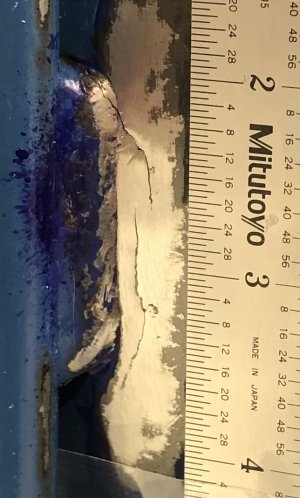

The crack is maybe 1.5” long… gulp… 3 gallons at 120 PSI is a lot of energy…

Should I:

1) Buy a new compressor.

2) Buy a new compressor and a lottery ticket.

3) Try to find a replacement tank.

4) See if I can get it repaired.

It probably has only 100 to 200 hours of running spread over 20 years, with the air tank drained after each use.

The crack is maybe 1.5” long… gulp… 3 gallons at 120 PSI is a lot of energy…

Should I:

1) Buy a new compressor.

2) Buy a new compressor and a lottery ticket.

3) Try to find a replacement tank.

4) See if I can get it repaired.