Along the theme of the ER40 collet nut I have a square and a hex ER32 collet holder sitting in my AliExpress shopping cart.

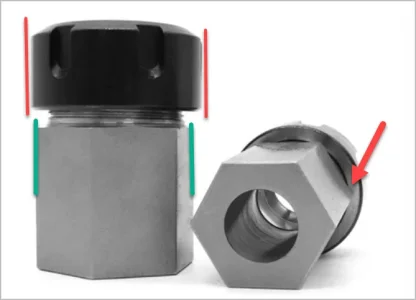

But then I started thinking are these really needed if one has a 4th axis with ER32 collet holder already mounted on the mill. Something like this:

Is there really then a need for the vise mounted version?

But then I started thinking are these really needed if one has a 4th axis with ER32 collet holder already mounted on the mill. Something like this:

Is there really then a need for the vise mounted version?