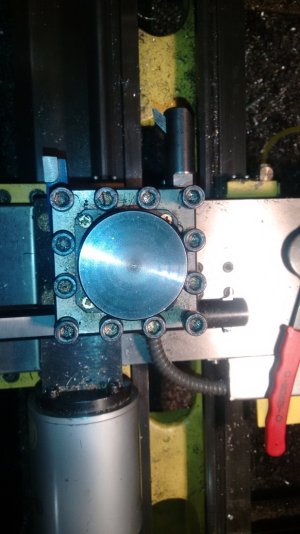

The project is to reproduce some ball joints out of steel. The parts are available at the truck shop but just too expensive. I uploaded the original and the part I made in my little lathe. It was a challenge but a really fun one. One of my buddy's wrote the program and we ran just the first of many today.

this is the store bought original. Below is what we turned on the CNC.

this is the store bought original. Below is what we turned on the CNC.

this is the store bought original. Below is what we turned on the CNC.

this is the store bought original. Below is what we turned on the CNC.

Last edited: