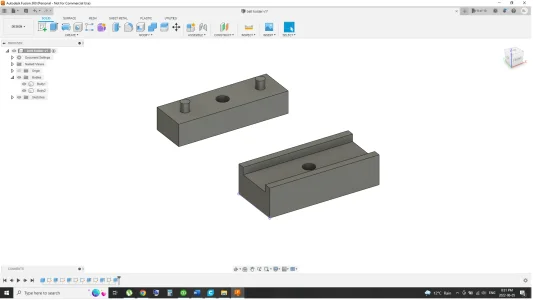

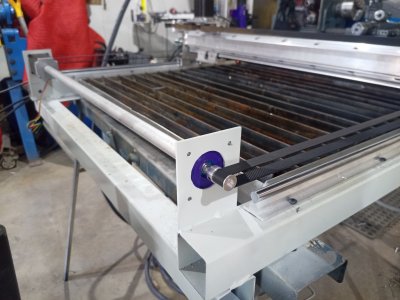

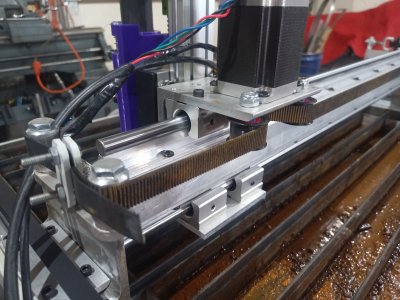

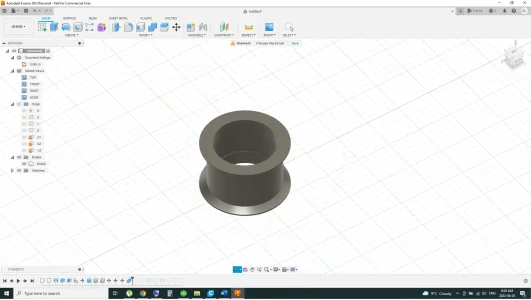

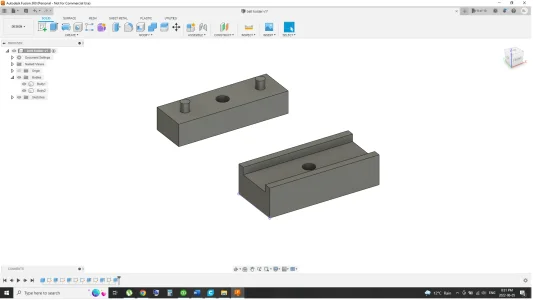

been working on this for a little bit now, its pretty much a langmuir systems cross fire knock off, i bought the stl files off jdsgarage for the bearing blocks (and plans...wich i have deviated quite a bit). im not sure how long the 3d printed bearings blocks will last...time will tell

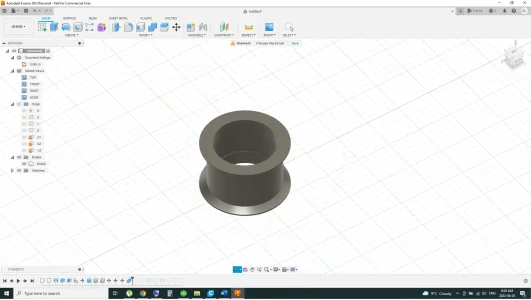

i designed a few of the msc pieces and 3d printed them, i have a bit to go yet, but its coming along

i designed a few of the msc pieces and 3d printed them, i have a bit to go yet, but its coming along