gerritv

Gerrit

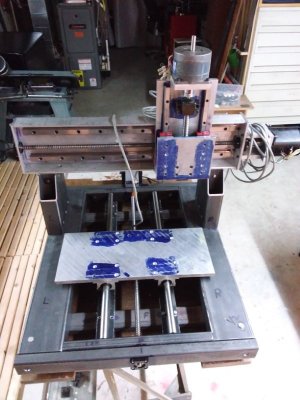

I started building this in Feb this year after seeing Stefan Gotteswinter's Stepmores SM4040 in action on YT. The machine is just the right size for my perceived needs.

Built up from 1/8" wall 2x4, 2x2 and 1x2 steel tube. Joints are with T Bolts, furniture style. made from 1/2" CR steel. Main assembly is with 5/16-16 SHCS.

The Z axis is built up of aluminum plate, X Axis is 6x2 aluminum U Channel salvaged from Univac II tapedrive from 1958 (I worked for Univac at Ont Hydro and helped scrap the Univac II's they had in 1968) A true justification for 'you never know when you might need it' hoarding.

Ball screws are Thomson 1/2 salvaged from a 1980's digitizer from Bata Shoes as are the Y axis rails and bearings.

Spindle will be water cooled ER20 via Aliexpress.

Software is Pathpilot using a Mesa 7I92h and an old PMDX-132 bob.

Should be running sometime in October at present slow rate of progress.

Built up from 1/8" wall 2x4, 2x2 and 1x2 steel tube. Joints are with T Bolts, furniture style. made from 1/2" CR steel. Main assembly is with 5/16-16 SHCS.

The Z axis is built up of aluminum plate, X Axis is 6x2 aluminum U Channel salvaged from Univac II tapedrive from 1958 (I worked for Univac at Ont Hydro and helped scrap the Univac II's they had in 1968) A true justification for 'you never know when you might need it' hoarding.

Ball screws are Thomson 1/2 salvaged from a 1980's digitizer from Bata Shoes as are the Y axis rails and bearings.

Spindle will be water cooled ER20 via Aliexpress.

Software is Pathpilot using a Mesa 7I92h and an old PMDX-132 bob.

Should be running sometime in October at present slow rate of progress.