-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

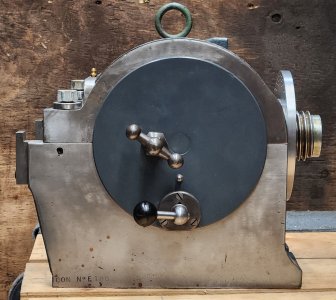

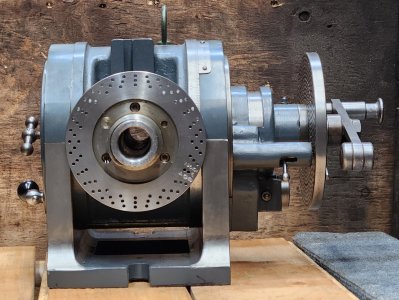

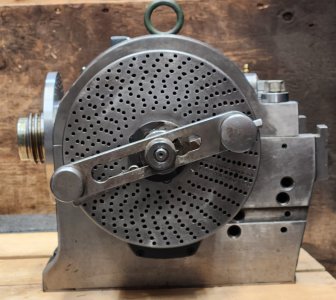

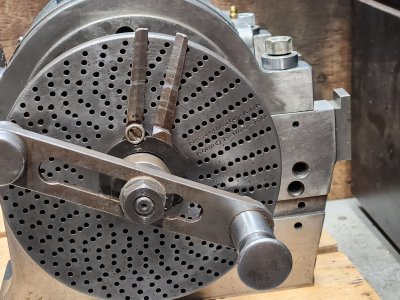

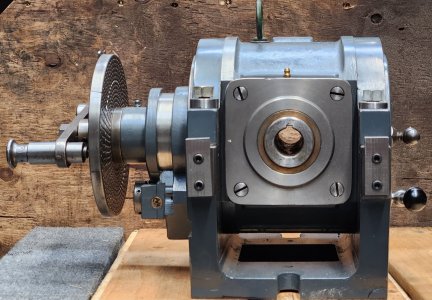

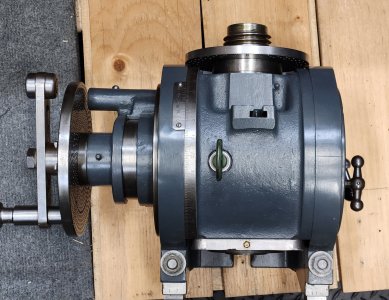

Cincinnati? Dividing Head

- Thread starter thestelster

- Start date

Some more pictures.

Attachments

-

20230522_182344.jpg321.4 KB · Views: 32

20230522_182344.jpg321.4 KB · Views: 32 -

20230522_183357.jpg458.7 KB · Views: 30

20230522_183357.jpg458.7 KB · Views: 30 -

20230522_183455.jpg488.4 KB · Views: 24

20230522_183455.jpg488.4 KB · Views: 24 -

20230522_183842.jpg465.4 KB · Views: 25

20230522_183842.jpg465.4 KB · Views: 25 -

20230522_183954.jpg478.3 KB · Views: 22

20230522_183954.jpg478.3 KB · Views: 22 -

20230522_184120.jpg365 KB · Views: 22

20230522_184120.jpg365 KB · Views: 22 -

20230522_184244.jpg469.4 KB · Views: 22

20230522_184244.jpg469.4 KB · Views: 22 -

20230522_184337.jpg484.5 KB · Views: 24

20230522_184337.jpg484.5 KB · Views: 24 -

20230522_184443.jpg522.7 KB · Views: 29

20230522_184443.jpg522.7 KB · Views: 29 -

20230522_185301.jpg677 KB · Views: 31

20230522_185301.jpg677 KB · Views: 31 -

20230522_190413.jpg401.3 KB · Views: 38

20230522_190413.jpg401.3 KB · Views: 38

John Conroy

member

There's ifo on vintage machinery on Carroll dividing heads.

Dabbler

ersatz engineer

It seems that someone wanted 900US$ for one:

John Conroy

member

Made in Cincinnati and supposed to be very high quality. You got a gem!

I don't think it's a Carroll Dividing Head. It doesn't look like any of the ones I saw online. I think it's an early Cincinnati, missing some parts, and possibly repainted. Or a Cincinnati clone. But the brass plate underneath with the adjustment instructions, is in good English, and overall it is quite well made.

John Conroy

member

Looks like the footstock is genuine Carroll, does it not match the dividing head?

Hi John, it is of the appropriate height, and it is well made, but it doesn't look like a Cincinnati, and is slightly different from the Carroll ones I have seen on-line, but who knows. Both units I have are quite nice. I do have to completely fabricate the mechanism which attaches to the DH which allows for direct indexing on the spindle plate. The indexing pin has a rack which is levered into position by a lever. The whole unit will move up or down to correspond to one of the 3 dividing circles of the spindle plate.Looks like the footstock is genuine Carroll, does it not match the dividing head?

I also have to determine what the spindle taper is. It looks like an MT4 and one will go in, but according to the some literature its a BS taper, so I will have to measure it and find out.

So now that I managed to get this beast onto the milling machine table, I determined that the spindle has a Brown & Sharpe #10 taper.

Also, it's been repainted, and unfortunately whoever did the job thought that the oil nipples were too much of a bother to tape up or remove. They are funny looking nipples that I've not seen before. Like soft point .22 lead bullets.

I removed two, and they look to be app. 6mm and tapered. So I will have to get new ones all around. Possibly cups?

And I think I'll total disassemble, remove paint, clean up.

Also, it's been repainted, and unfortunately whoever did the job thought that the oil nipples were too much of a bother to tape up or remove. They are funny looking nipples that I've not seen before. Like soft point .22 lead bullets.

I removed two, and they look to be app. 6mm and tapered. So I will have to get new ones all around. Possibly cups?

And I think I'll total disassemble, remove paint, clean up.

Attachments

Well, I took it apart, taking tons of pictures so I can put it back together. Theres a few little issues I have to deal with, and might consider machining the spindle internal taper from Brown & Sharpe #10 to MT4, if I can figure out how to do a perfect concentric job.

I hope I haven't bitten off more than I can chew!!

I hope I haven't bitten off more than I can chew!!

Attachments

I hope I haven't bitten off more than I can chew!!

If anyone can handle that, you can!

Haha! I don't know about that, but thanks for the vote of confidence.If anyone can handle that, you can!

Yesterday I confirmed several things which I have known for quite a while:

1. That making some very simple parts can take way longer than you could have imagined. (T-bolt)

2. I tend to over complicate simple parts. (T-bolt)

3. I need a way larger rotating table. The 6" is fine for holding a chuck or center, but useless for holding other items, i.e. vise.

4. You guys who refurbish and restore whole machines...hats off to you. I kneel to your patience and perseverance.

1. That making some very simple parts can take way longer than you could have imagined. (T-bolt)

2. I tend to over complicate simple parts. (T-bolt)

3. I need a way larger rotating table. The 6" is fine for holding a chuck or center, but useless for holding other items, i.e. vise.

4. You guys who refurbish and restore whole machines...hats off to you. I kneel to your patience and perseverance.

Attachments

I need a way larger rotating table. The 6" is fine for holding a chuck or center, but useless for holding other items, i.e. vise.

Ya, it looks kinda lost. I have a 10 and I wish it was 12. It never ends. I'll have to watch for a bigger one for you. Be a good way to get you to visit!

Dabbler

ersatz engineer

@thestelster Be on the lookout for a bargain table, but there is a stop gap measure that you can do in the mean time... Get a plate of steel or aluminum - I used 3/4 in thick 2024 aluminum on mine (about 10"X10")- and drill/tap it as a fixture plate, with some of the holes aligned with your T slots to hold it on the RT. No need to make a centring device, as everything you use on it will be done using hold downs anyway...

This will give you a 10X10 or 12X12 rotary fixture plate to hold your vise or other bigger items until you can find your bargain table.

I'm planning to make a 16" one for my 10 inch table as project #26,271

This will give you a 10X10 or 12X12 rotary fixture plate to hold your vise or other bigger items until you can find your bargain table.

I'm planning to make a 16" one for my 10 inch table as project #26,271

I never thought of that! Though, I find with this RT, maybe because it's light or cheap, that it doesn't take a lot to start chattering, and then I have to tighten down everything, and then it makes it difficult to rotate the table.@thestelster Be on the lookout for a bargain table, but there is a stop gap measure that you can do in the mean time... Get a plate of steel or aluminum - I used 3/4 in thick 2024 aluminum on mine (about 10"X10")- and drill/tap it as a fixture plate, with some of the holes aligned with your T slots to hold it on the RT. No need to make a centring device, as everything you use on it will be done using hold downs anyway...

This will give you a 10X10 or 12X12 rotary fixture plate to hold your vise or other bigger items until you can find your bargain table.

I'm planning to make a 16" one for my 10 inch table as project #26,271

99% of the time I use it in the upright position like a dividing head to do flutes or octagon profiles. So it never rotates while cutting.

HELP!!

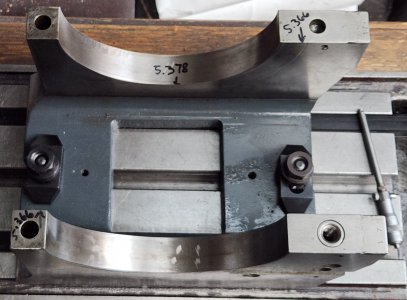

When I got this dividing head, I wanted to rotate the head a couple of degrees, but it wouldn't budge, no matter how much reasonable force I used. I figured it was just frozen solid with dried goop. So I completely disassembled and cleaned and now ready to reassemble. I wanted to test the fit of the head in its saddle, but wouldn't go in. Upon closer inspection and measurements, it appears that it has sprung

(See picture for measurements)

What do I do?

When I got this dividing head, I wanted to rotate the head a couple of degrees, but it wouldn't budge, no matter how much reasonable force I used. I figured it was just frozen solid with dried goop. So I completely disassembled and cleaned and now ready to reassemble. I wanted to test the fit of the head in its saddle, but wouldn't go in. Upon closer inspection and measurements, it appears that it has sprung

(See picture for measurements)

What do I do?