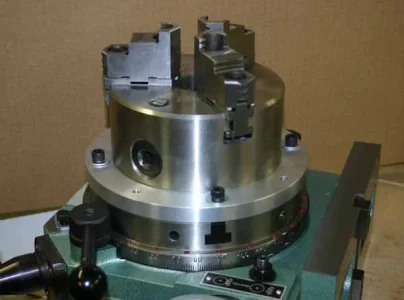

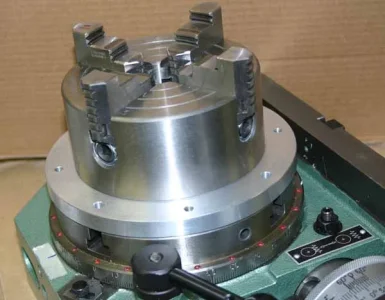

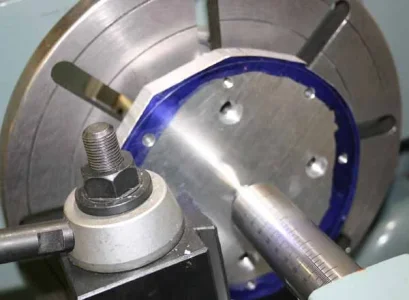

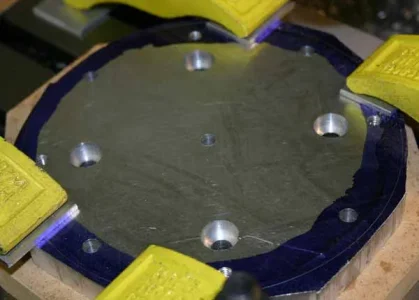

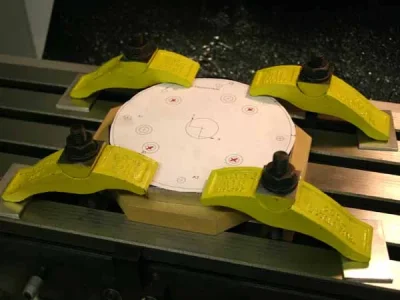

I got this 5" 4-jaw plain back chuck because it was the right size for my 6" rotary table. Its a Gator (Chinese) but seems pretty decent for the cost. Here is how I machined an adapter plate to marry the two. I decided to turn a close fitting male boss protrusion that fits the chuck recess as opposed to flat surface relying on bolts & friction to stay put. I'm not convinced its 100% necessary because right now that's how the plate attaches to RT platen but figured it cant hurt either. If I do experience any plate movement I have one more trick - an MT stub located in the RT bore with a machined disc that fits the center hole of the plate.

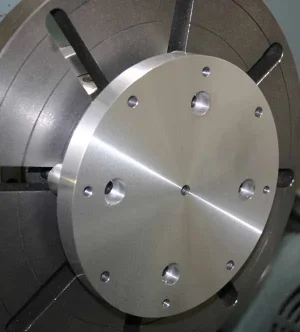

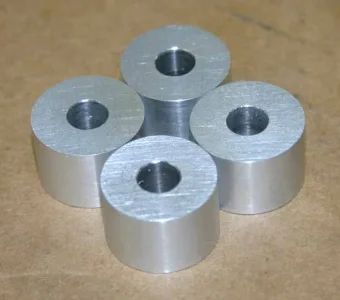

Ideally I would have preferred cast iron or steel for durability but I had this 5/8" cast aluminum tooling plate stock so figured I'd give it a go. I'll just have to have to be careful not to ding it up, but accuracy wise it turned out decent. Tooling plate machines like the hard alloys (2024 or 7075) & holds tolerances well. I was a little apprehensive about turning the rough stock with those standoff donuts sandwiched between the faceplate (another reason I was kind of chicken of steel). It went clunkety-clunk until stock became round but nothing moved or flew off. Now I'm more confident CI or steel could be done the same way as long as the cuts & speed was moderate.

Now with this under my belt I want to make a tooling plate with an array of threaded holes so I can clamp irregular parts & machine them on the lathe faceplate.

Ideally I would have preferred cast iron or steel for durability but I had this 5/8" cast aluminum tooling plate stock so figured I'd give it a go. I'll just have to have to be careful not to ding it up, but accuracy wise it turned out decent. Tooling plate machines like the hard alloys (2024 or 7075) & holds tolerances well. I was a little apprehensive about turning the rough stock with those standoff donuts sandwiched between the faceplate (another reason I was kind of chicken of steel). It went clunkety-clunk until stock became round but nothing moved or flew off. Now I'm more confident CI or steel could be done the same way as long as the cuts & speed was moderate.

Now with this under my belt I want to make a tooling plate with an array of threaded holes so I can clamp irregular parts & machine them on the lathe faceplate.

Attachments

-

IMG_5556_edited-1.webp32.9 KB · Views: 11

IMG_5556_edited-1.webp32.9 KB · Views: 11 -

IMG_5555_edited-1.webp21.4 KB · Views: 8

IMG_5555_edited-1.webp21.4 KB · Views: 8 -

IMG_5554_edited-1.webp15.3 KB · Views: 8

IMG_5554_edited-1.webp15.3 KB · Views: 8 -

IMG_5552_edited-1.webp15.1 KB · Views: 8

IMG_5552_edited-1.webp15.1 KB · Views: 8 -

IMG_5549_edited-1.jpg36.7 KB · Views: 8

IMG_5549_edited-1.jpg36.7 KB · Views: 8 -

IMG_5547_edited-1.webp24.1 KB · Views: 9

IMG_5547_edited-1.webp24.1 KB · Views: 9 -

IMG_5538_edited-1.jpg36.5 KB · Views: 8

IMG_5538_edited-1.jpg36.5 KB · Views: 8 -

IMG_5536_edited-1.webp27 KB · Views: 7

IMG_5536_edited-1.webp27 KB · Views: 7 -

IMG_5537_edited-1.webp26.9 KB · Views: 8

IMG_5537_edited-1.webp26.9 KB · Views: 8 -

IMG_5533_edited-1.webp25.7 KB · Views: 8

IMG_5533_edited-1.webp25.7 KB · Views: 8 -

IMG_5530_edited-1.webp26.9 KB · Views: 8

IMG_5530_edited-1.webp26.9 KB · Views: 8