If you believe the skate bearing vendors, what the average skate boarder needs is ABEC 9 bearings and they'll sell them to you for $3.99 each. Point is, there's not a roll-your-eye's smilie big enough to describe the BS regarding some of this bearing stuff.

Here's a few things I would say are current truths - and its changed a lot over the years, and some ideas what you might use for this application. A bit verbose, but lots to say

- The world's low cost providers, and their propensity to arbitrarily claim whatever class or certs they think the customer wants to hear (something that is truism of that supply chain across product lines, read "

Poorly made in China" for example) means unless you are buying from someone who's a part of the big manufactures supply chain, you have no idea what you getting. Buy from industrial houses that sell SKF, NSK etc. You buy from Aliexpress, Amazon or Ebay, you have no idea what you are getting....but they might be great for skateboarding!

- The cost varies with size obviously, but also with class. Regular SFK AC's are P5 (an ISO class) and SKF Super Precision AC's are P4. Magnitudes of price difference between the two. P4 are roughly the equivalent of ABEC 7, but as bearing sizes are 99% metric as are the makers, giving the ISO class makes sense. With ISO, a smaller number is a higher class (overall greater precision, less runout) and with ABEC a higher number is a better class

- Bearings are better than ever and often better than their stated class. Super accurate modern CNC's make things easier to keep to tighter tolerances. I've spoken with bearing mfg engineers from two different mfg's who state that there is no difference between the manufacturing of a say a P5 bearing and a p4 bearing, the price difference is from the additional time to quantify and certify that it meets P4 standards. Maybe there is the odd reject from the P5 pile, so there is value in buying the P4's, but in lots of cases the P5's would be just as good.

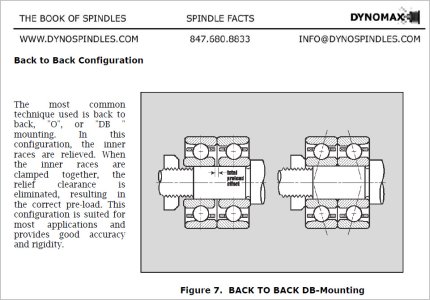

- The final jump in price comes when you get matched sets of P4's I've bought a lot these over the years, this is where you spend $800 for pair sort of thing, and it hurts. You have to understand a little bit about how AC's work to appreciate it. There has to a be a preload with AC's and for most machines, that is determined by either the difference in thickness between the inner and outer race (in the case of matched) or the thickness of the spacers (you're grind them to create preload). You can, and I've done so, grind the spacers to create the preload you want and then P4 universals become the same as P4 matched, but the situation doesn't always allow for it - e.g. replacing existing back to back arrangements with room for spacers. Even with this, non-matched are now called universal and come with a preset preload...another example of overall manufacturing quality improving imo. The advantages of matched P4's imo is literally, getting very small.

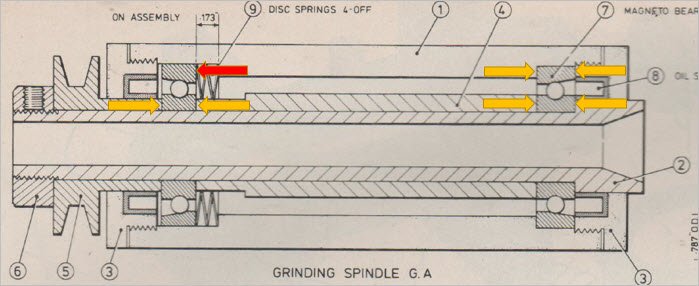

- All the tool post grinders I've had apart use a spring to create preload - there is hardly axial force so it works. In such a case, there is zero need for spacers or matched pairs. You do not need the 800 bearings, nor would give any advantage.

- Several TPG use magneto bearings, not a particularly high end solution, but it just says they can still work when things are less than perfect

- Deep groove ball bearings (even the good quality ones are cheap and P5's are likely as good as P4's) with either a spring or belleville wash arrangement giving a bit of preload is an option. This is how a unimat spindle for example is set up. Or how a Boley 82 or 83 is done (one of the highest end watchmakers....although I confess I converted mine to AC's

). There is so little axial force in grinding it might be good way to go.

Hope that helps. Unless you are into matched super precision sets, good quality bearings from reputable makers are reasonably enough priced that imo its make no sense to use mystery bearings. After how much time goes into a project it seems (to me anyway) false economy to cheap out on the the mission critical part of a spindle. I'd go SKF P5's AC's, (which are not matched and I believe have a universal preload) and set the preload up with a spring. Probably <$80 depending size, but you'd putting top quality bearings into it, worthy of the considerable amount of time you'll be putting into the project