Couple hour project that has been a month in the making waiting on tools etc

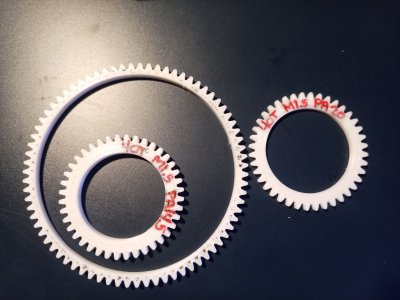

lathe was missing several teeth on one of the change gears, after making a guess as to what gear type/pressure angle/etc i printed a couple options on the 3d printer to make sure i ordered the correct cutter, and after the long 3 week wait from china ive been able to start and complete this little repair

now im sure i could have paid a member to repair this gear for far less than the 500$ i spent on an arbor, dividing head, and cutter set just to cut a couple teeth.....but where is the fun in that

the process involved making an arbor to hold the gear, grinding the areas with the broken teeth away, filling with braze, turning the excess off, and finally setting the gear cutter and dividing head up and cranking that handle 75 times

lathe was missing several teeth on one of the change gears, after making a guess as to what gear type/pressure angle/etc i printed a couple options on the 3d printer to make sure i ordered the correct cutter, and after the long 3 week wait from china ive been able to start and complete this little repair

now im sure i could have paid a member to repair this gear for far less than the 500$ i spent on an arbor, dividing head, and cutter set just to cut a couple teeth.....but where is the fun in that

the process involved making an arbor to hold the gear, grinding the areas with the broken teeth away, filling with braze, turning the excess off, and finally setting the gear cutter and dividing head up and cranking that handle 75 times