I had similar frustrations with the threading and feed charts on my first lathe (a House of Tools 12x36 FRV 30-GL300C). there was at least one error on the charts, and I was never really quite sure of what change gears were required to do what, or what all the possible feed and threading possibilities were since only a small subset of the possibilities are listed on the faceplates.

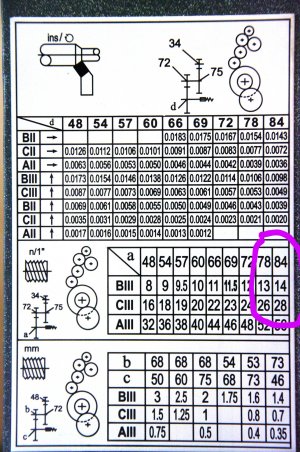

The lathe had a few external change gears, an MI/MII range lever, an A through E gear lever, and a 1 through 5 gear lever to set the internal gears that drove the lead screw and feed shafts.

So, I did some measuring to figure out what was in the internal gearbox, and built a spreadsheet to generate the true and complete feed rates and thread pitch tables.

I started out by digging up a couple of mechanical rotation counters from my hoarding stockpile. Something like these.

I mounted one in the chuck (easy) and the other at the end of the lead screw. I think I used a magnet and some glue to mount to the end of the leadscrew. Later, I did the same thing with the feed shaft.

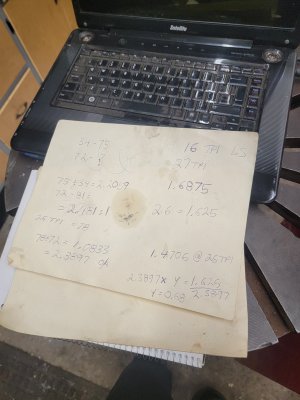

I then ran the lathe through a couple of hundred chuck rotations in each gear setting (with one fixed set of external change gears), and logged the results in a spreadsheet.

"A-E" and "1-5" are the two gear setting handles on the lathe. With a little bit of guessing, from the calculated ratio of the chuck : leadscrew I figured out what the real internal gear ratios were for each gear setting.

Some were easier to guess at than others. The easy ones are listed above. I then made some more sub tables in the spreadsheet to look at the ratios for just the A-E changes and the 1-5 changes when I normalized one of the ratios to 1:1, which gave me the ratios that each gear lever accomplished:

This did not tell me the actual number of teeth in the internal gears, but left me about 99.9999% sure of what the exact tooth ratios were for each gearbox setting. There was another setting: MI/MII, but that was easy, it was a simple 1:2 ratio.

I have attached V1 of my lead/feed calculator for further analysis of it it helps anybody. The two tables above are from this spreadsheet.

If there is interest, I can post the final version of the spreadsheet that created nice tables of all the lathe settings, and what I did to figure out the same stuff for my replacement Colchester-style knock off - which uses a very common type of feed gearbox (using levers often labeled: C-D-E, R-S-T, W-X-Y-Z, and 1 through 8) that does not generally require any change gears for metric or imperial threads.

I have found having this data to be invaluable to using the lathe.