-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

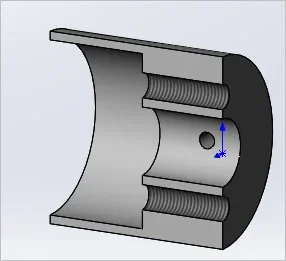

Carriage Stop

- Thread starter Crosche

- Start date

i am in need of one of those. what grade of material did you use?

i am in need of one of those. what grade of material did you use?

The body is CR mild steel, the bolts are 4140 and the bolt handles are 1/4" drill rod.

Did you use the thecogwheel drawings?

Yes, I started with his drawings and modified them to fit my lathe. Also, I tried his method of rust bluing which I had limited success with.

Did you use the thecogwheel drawings?

What's that?

DPittman

Ultra Member

Looks good. I finally made one a while back also and they are very useful. I have a cheap dro on my lathe but having the physical bump stop is still nice.Just completed this little project last night. I think that it will be a useful tool to have.

so, newbie question here......

My power feed clutch on my new lathe was set so tight that I know it would easily push a stop-block down the ways. I've adjusted it, but I'm wondering what process other are doing. I don't want it set so slight that resistance due to the DOC would affect it, but yet would really like to use it for critical stops where stop means stop (not crash).

I'm pretty sure when I got my lathe I couldn't stop it manually with my body weight/hands.

My power feed clutch on my new lathe was set so tight that I know it would easily push a stop-block down the ways. I've adjusted it, but I'm wondering what process other are doing. I don't want it set so slight that resistance due to the DOC would affect it, but yet would really like to use it for critical stops where stop means stop (not crash).

I'm pretty sure when I got my lathe I couldn't stop it manually with my body weight/hands.

I might be wrong but I consider the power feed clutch on my lathe there only to prevent catastrophic damage. Either driving into the chuck or any kind of lock up on the carriage where it would disconnect before taking out the head stock power train. I have heard of people doing what you are talking about but having examined my clutch mechanism, I think its a bit mickey mouse. I think using it a lot will wear the springs, balls & vee-groove pretty quick. The springs are a bugger to get btw as well

DPittman

Ultra Member

I suppose it would depend on how you make your carriage stop, but I think they can be made to clamp tight enough that they wouldn't move. I dont have a clutch on my little lathe but I know something would give before the carriage stop would ever move.so, newbie question here......

My power feed clutch on my new lathe was set so tight that I know it would easily push a stop-block down the ways. I've adjusted it, but I'm wondering what process other are doing. I don't want it set so slight that resistance due to the DOC would affect it, but yet would really like to use it for critical stops where stop means stop (not crash).

I'm pretty sure when I got my lathe I couldn't stop it manually with my body weight/hands.

So what is actually stopping the carriage ? The feed rod won’t stop, so is there a second slip clutch inside the apron?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

DPittman

Ultra Member

So the way I use a carriage stop is never with power feed....it is only to stop the carriage when hand feeding it up to a spot like a shoulder.So what is actually stopping the carriage ? The feed rod won’t stop, so is there a second slip clutch inside the apron?

Sent from my iPhone using Tapatalk

Manual turning, understood, was wondering if anyone used the clutch as a feature to use with power feed

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

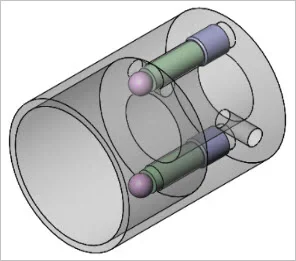

Some pics of my clutch. Hopefully you can see the principle. The spring tension against the ball is compressed by the set screw. More infeed of screw = more spring tension = higher breakout torque. Once it see's a certain torque, the balls come out of the vee grooves with rackety-clack. Almost like it was designed you wake you up LOL. Maybe better lathes have real clutches with friction plates or whatever. I think I ran a file across the vee part & it didn't seem (too) hard. That's why I say in my own case I wouldn't trust this for repeated use. I find it easy enough to powerfeed up to the end, then disengage & hand feed the last 0.1" to the carriage stop.

Attachments

DPittman

Ultra Member

I've seen ( not in person) adaptations to lathes that use a dog style clutch in the drive train to stop the carriage with power feed. They are used for threading but I suppose you could set them up for any sort of power feed carriage work. I've got loose plans for making one for my lathe someday ( ya you know those someday projects)Manual turning, understood, was wondering if anyone used the clutch as a feature to use with power feed

Sent from my iPhone using Tapatalk

I researched this very subject 2 years ago wondering the same thing. Apparently some lathes are good to go for power feeding to a stop when using what they call a hard stop (i.e. mechanically braced back to the head stock).

Probably depends upon what kind of clutch is in place. Mine is disk based but I've never knowingly caused it to slip.

Practical Machinist has a couple of threads on this subject include what typical clutch ft-lb settings should be.

My first attempt at a stop was in mild steel 7/8" wide with a single clamping screw and it didn't hold at all. My second attempt was in 1.5" wide aluminum with two clamping screws and that one seems to hold really well.

Probably depends upon what kind of clutch is in place. Mine is disk based but I've never knowingly caused it to slip.

Practical Machinist has a couple of threads on this subject include what typical clutch ft-lb settings should be.

My first attempt at a stop was in mild steel 7/8" wide with a single clamping screw and it didn't hold at all. My second attempt was in 1.5" wide aluminum with two clamping screws and that one seems to hold really well.

I've seen that too. One thing to know is it kind of depends on the lathe. On mine you engage power feed mode or thread mode. They are two separate drive arrangements by setting knob/levers. In power feed mode the PF bar bar turns a worm gear in the apron which drives other gears, traversing the carriage along the gear rack on the way. In threading mode the PF is disengaged. The carriage advances when the clam shell lever is engaged on the rotating feed screw. Some lathes I guess combine these actions into the screw, no separate PF bar.

Premium lathes have better designed integrated trip out mechanisms. But then where is the drama & excitement of potentially crashing into things? Or hooking up threading tools upside down & other convoluted ways to thread away from headstock? LOL

Premium lathes have better designed integrated trip out mechanisms. But then where is the drama & excitement of potentially crashing into things? Or hooking up threading tools upside down & other convoluted ways to thread away from headstock? LOL