terry_g

Ultra Member

I have recently purchased some inexpensive insert tooling for my lathe and now am wondering why I waited so long. I know when you buy a 10 pack of inserts for less than $20 they aren't going to be high quality carbide.

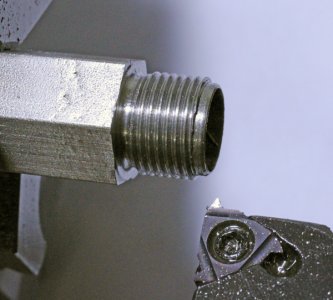

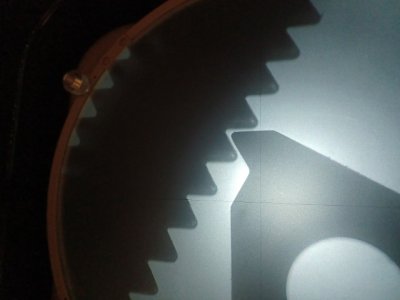

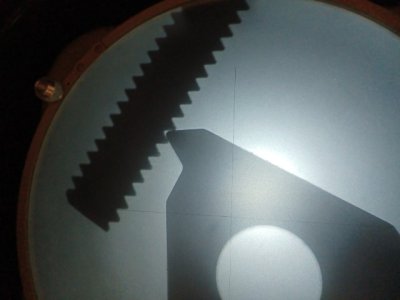

I bought a 12mm internal threading bar that take 11IR A60 inserts that will cut 48 to 16 threads per inch. I have been using high speed steel and brazed carbide for years. One of the thing I learned a long time ago was the need for a radius on the tip of the cutting edge. A sharp point is very easy to chip. A .010" radius on a high speed steel bit is usually adequate, a little more .015" to .020" on a brazed carbide bit really helps. The threading inserts I have a sharp point and not a radius. Turning inserts have a few options for different radius's but the threading inserts do not.

Last night I was turning a 20 TPI internal thread and about three cuts from finished the tip of the insert chipped. I ended up chipping all three cutting edges by the time I was finished. I took a diamond file and put a slight radius on the least damaged cutting edge and did the finish cut with it. When cutting a 20 TPI thread in a deep bore with a small threading bar the bar the bar is very close to the thread and I suspect a cutting got between the bar and the thread and made it flex away and then dig in chipping the bit.

I bought a 12mm internal threading bar that take 11IR A60 inserts that will cut 48 to 16 threads per inch. I have been using high speed steel and brazed carbide for years. One of the thing I learned a long time ago was the need for a radius on the tip of the cutting edge. A sharp point is very easy to chip. A .010" radius on a high speed steel bit is usually adequate, a little more .015" to .020" on a brazed carbide bit really helps. The threading inserts I have a sharp point and not a radius. Turning inserts have a few options for different radius's but the threading inserts do not.

Last night I was turning a 20 TPI internal thread and about three cuts from finished the tip of the insert chipped. I ended up chipping all three cutting edges by the time I was finished. I took a diamond file and put a slight radius on the least damaged cutting edge and did the finish cut with it. When cutting a 20 TPI thread in a deep bore with a small threading bar the bar the bar is very close to the thread and I suspect a cutting got between the bar and the thread and made it flex away and then dig in chipping the bit.

Last edited: