TorontoBuilder

Ultra Member

I have about 85 squarish carbide cutters that came off a helical jointer.

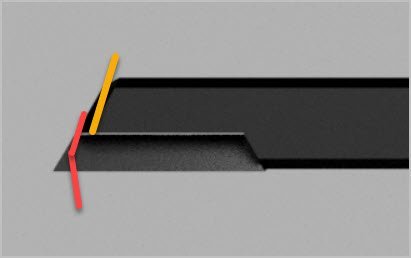

They're ~15mm x 15mm x 2.5mm with each cutting edge being a 150mm radius with 30 degree relief angle on the back. They have holes for a 6M torx bolt (of which I have about 100). The inserts look like this:

I thought about milling bar stock to make handles. The tip would have a 2.5mm recess with a radius rear wall at 30 degrees to mate with the cutter. I'd cut that with a ground HSS insert in a simple fly cutter.

I can make short handles, long handles, tool insert handles... bend, straight...

suggestions, thoughts etc welcomed

They're ~15mm x 15mm x 2.5mm with each cutting edge being a 150mm radius with 30 degree relief angle on the back. They have holes for a 6M torx bolt (of which I have about 100). The inserts look like this:

I thought about milling bar stock to make handles. The tip would have a 2.5mm recess with a radius rear wall at 30 degrees to mate with the cutter. I'd cut that with a ground HSS insert in a simple fly cutter.

I can make short handles, long handles, tool insert handles... bend, straight...

suggestions, thoughts etc welcomed