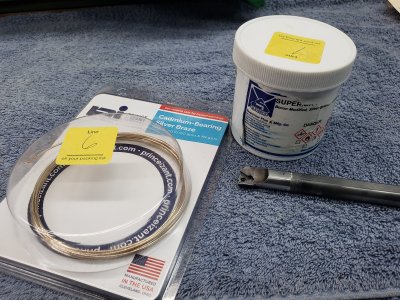

About 2-3 years ago, maybe more, I was boring out something or other, can't remember, and the head of my 1/2" carbide boring bar snapped off. Several months ago I watched a couple of YouTube videos by Stefan and Renzetti, brazing heads to carbide shafts, so I figured I should get the proper flux and silver braze. Well today I fixed it up. After I cleaned it up, I smacked it as hard as I could on a hardwood block a number of times, and it didn't go flying off. I'll have to test it another day.

Attachments

-

20220924_151217.jpg611.6 KB · Views: 19

20220924_151217.jpg611.6 KB · Views: 19 -

20220924_151401.jpg323.1 KB · Views: 21

20220924_151401.jpg323.1 KB · Views: 21 -

20220924_152709.jpg342.6 KB · Views: 22

20220924_152709.jpg342.6 KB · Views: 22 -

20220924_155228.jpg476.2 KB · Views: 22

20220924_155228.jpg476.2 KB · Views: 22 -

20220924_155255.jpg207.4 KB · Views: 21

20220924_155255.jpg207.4 KB · Views: 21 -

20220924_160157.jpg149.6 KB · Views: 20

20220924_160157.jpg149.6 KB · Views: 20 -

20220924_165044.jpg612.1 KB · Views: 20

20220924_165044.jpg612.1 KB · Views: 20 -

20220924_165128.jpg153.8 KB · Views: 20

20220924_165128.jpg153.8 KB · Views: 20 -

20220924_165213.jpg175.5 KB · Views: 20

20220924_165213.jpg175.5 KB · Views: 20