My made in Manitoba AC Welder has taps for: 25A; 50A; 75A; and 100A.

For my Mill stand, I need to weld 2”x2”x1/4” thick square tubing at 90 degrees to each other.

I’ve been looking at TimWeld’s Youtube channel and he recommends:

- 6061 for penetrating welds (butt joints).

- 7018-AC for general welds.

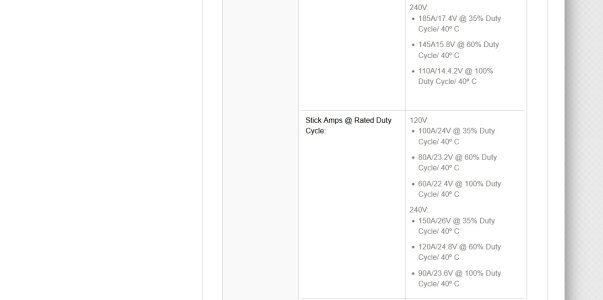

From the labels on the Princess Auto 3/32” welding electrodes they suggest I’ll need a welder that can deliver 100A. My welder can’t deliver enough amperage for 1/8” electrodes.

I’ve got some offcuts from cutting the tubing, and I plan to practice on these until I’m confident enough to tackle the stands welds. I can cut these to see what the welds look like.

So onto my question… whats the opinion on whether 3/32” rods be adequate to weld with? (likely with multiple passes)

For my Mill stand, I need to weld 2”x2”x1/4” thick square tubing at 90 degrees to each other.

I’ve been looking at TimWeld’s Youtube channel and he recommends:

- 6061 for penetrating welds (butt joints).

- 7018-AC for general welds.

From the labels on the Princess Auto 3/32” welding electrodes they suggest I’ll need a welder that can deliver 100A. My welder can’t deliver enough amperage for 1/8” electrodes.

I’ve got some offcuts from cutting the tubing, and I plan to practice on these until I’m confident enough to tackle the stands welds. I can cut these to see what the welds look like.

So onto my question… whats the opinion on whether 3/32” rods be adequate to weld with? (likely with multiple passes)