It allows you to thread metric onto Imperial, Imperial onto BA, coarse, fine, anything you like really. The thread lines smear a bit but definitely no galling or seizing (haha just kidding, Janger would have to answer that).

Now if you had a die grinder in there with appropriate profile point, we'd be cook'n. I think Stefan did something along those lines with his Deckel spindle detached.

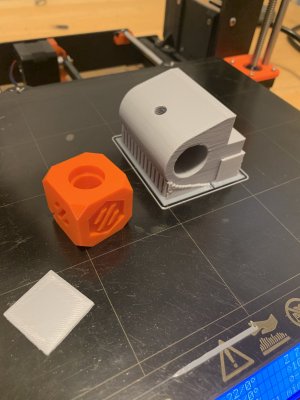

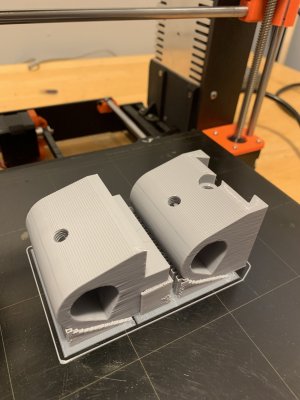

One thing I would say is holding different size permutations of cylindrical things, opposing Vee grooves are a better design feature. You have 4 tangent lines of contact area vs one with a bolt (point) on the other side. But then it would be some kind of clam shell, more parts etc

View attachment 27463