First off, I’m still very new to machining, and might not have all the terms right.

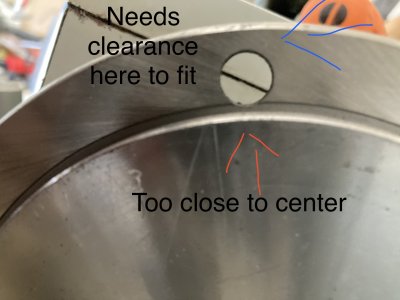

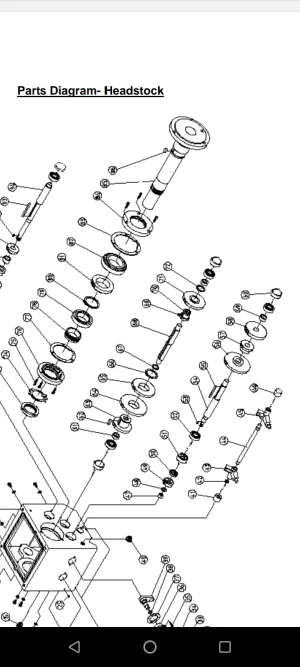

I have a used cx709 lathe I picked up a couple years ago. Yesterday I tried to fit the 4 jaw chuck to it, but the screw holes in the backing plate don’t line up to the holes in the chuck. The 3 jaw is fine, and so is the face plate (they use the same mounting holes).

Can I enlarge the holes in the backing plate to fit, or is there a better option?

Thought I’d ask before I do something I’ll regret.

I’ve attached a couple photos to hopefully show the issue.

I have a used cx709 lathe I picked up a couple years ago. Yesterday I tried to fit the 4 jaw chuck to it, but the screw holes in the backing plate don’t line up to the holes in the chuck. The 3 jaw is fine, and so is the face plate (they use the same mounting holes).

Can I enlarge the holes in the backing plate to fit, or is there a better option?

Thought I’d ask before I do something I’ll regret.

I’ve attached a couple photos to hopefully show the issue.