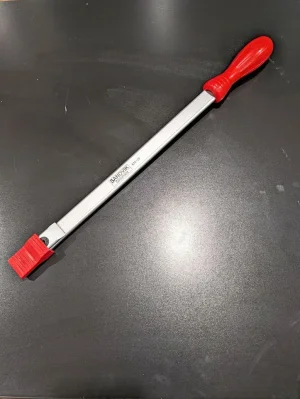

If a Biax isn't in the works, here's the next best thing....... (sorry but I don't think Amazon ones would be much good, too short, you need a bit of flex in it)

I've heard many talking about attempting to make a power scraper but I've not seen one report back that it worked. Maybe you'll be the first (please take lots of photos), however tons of machines have been done with hand scrapers. I have a biax and still usually finish with hand scraper. Its slower, but also somewhat less tiring as the biax is heavy.

All the above are bits of carbide silver solder to a shank and then a file handle is installed. Its really worth it to make them out of carbide. Make a bunch as its nicer being able to sharpen a batch then work your way through them.....they need constant sharpening. Cutting angle is about 92 - 93 degrees, else it can dig in its a misery.

Next up, sharpening. Your DOC when scraping is about a tenth of a thou. As such, it needs an extremely fine edge or it will just bounce over the surface. The way to do this is with cast iron wheel and 10 micron diamond paste. Lap the sides of the carbide to a mirror before silver soldering, then you just touch up the end on the diamond lap.

The laps have a taper mount (like a lathe) on hubs turned in situ on the shaft. This ensures next to no vibration. A crappy tire cheapo grinder and two cast iron disks.

After a few decades of of doing this, imo the above should save you a lot of heart ache.

Simple hand tools and simple principals let you achieve new factory (or better) precision, kind of like magical lol.