Chipper5783

Super User

Some back ground. I've been machining off/on for a while. I bought my first lathe in '83. Other machines have come and gone (mostly come). Of the years career and life have been on interesting twists and turns, but really all has been good. I've kept that initial interest in fixing and making things - somewhat career, specifically as a hobby. Fast forward ~30 years, I thought a CNC machine would be cool. I started looking, reading, talking. It seemed that for me, a CNC mill would hold the most potential (I've no doubt a CNC lathe would be cool, but the mill seemed more of a game changer in my application).

The hobby CNC mills seem fine, still not cheap and my other machines are commercial grade and decent size, so I could see I'd be wanting more. I'm very impressed by the conversion machines people build, but that felt quite daunting (much more to learn and really a lot of work to approach the features of a commercial machine). A full on commercial VMC came available right in my "neck of the woods". So I went and checked it out, 1998 Bridgeport VMC 1000, 4 axis, #40 taper, 22 tool changer, full enclosure, flood coolant, chip conveyor - connected and running. It even came with a bunch of tools. Well, it was "way too big for me", I would need to upgrade my little 5HP RPC, the rough price range was out of my league – the self rationalization not to get it continued (more power and features than I needed) and I walked away. I was still wanting to learn the market, so I did a follow up call 10 months later to find out what it sold for – apparently I was the only one who had inquired and the owner just wanted it gone. Strictly speaking an old CNC, even if it works like day #1 – has no commercial value (he was getting rid of it because of difficulties in keeping staff current, the new CNC machines are much more productive and easier to use, there were numerous minor issues) – as another business isn’t going to buy it (they would have all the same issues) and it is too much for a hobby guy. That makes the candidate ma

Humm, maybe all that capability wouldn’t be such a bad thing after all? It still cost some real money (per my bank account – but for a real machine it was crazy cheap). A condition of the purchase was to use an insured, industrial machinery mover to get it out of the building. It was not in a difficult location, but the owner was not going to tie up his guys or risk any of his other equipment with some armatures mucking around. The movers mobilized out of Calgary, pickup, kneel down low bed, #30,000 rated forklift – and $2500 later the job was done. In retrospect, paying for the move was a good deal. I’ve move several smaller regular machines (2000-3000 pounds) – but these guys did not rush, worked very safe, nothing anywhere was even scratched – and were totally done, start to finish in 4½ hours. Simply part of the cost of the machine.

The machine dominates my shop, but it has really grown on me. The power requirement rationalized a PhasePerfect (the PP cost as much as the machine plus the moving cost) – I should have bought the PP before, all the machines really like it. I certainly don’t regret, “too much power and too many features”.

At first I was scared of the antique electronics. Well, so far so good. The floppy drive converter turned out to be a configuration issue. The mystery lock ups of the MMI (man machine interface) may have been due to me connecting the 240V power where the shop had it hooked up (they were on 208V). I replaced the MMI computer, which is simply a Pentium on a half card board with a newer one from Aliexpress. That took some research, but others have been down that path (BP made quite a few VMCs in this or similar models) – apparently many equipment makers in various industries used PC based controls, so you can get a newer one quite easily. The tool changer did not index properly and I snapped a few gripper fingers. That turned out to be a configuration / power issue – and new grippers are still available (it seems this is a fairly common problem).

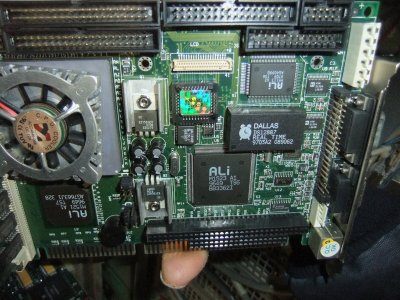

I have included a picture of the old board (the "Dallas" chip has the battery imbedded in it).

The machine was pretty clean – until I took the guards and covers off. I spent about a month cleaning. The tooling is BT40, and it was an odd-ball mix – so I’ve been purchasing the odd piece here and there. At new pricing, the tooling would have cost more than what I paid for the machine.

One challenge is that the controller is DX-32. Apparently it was a Bridgeport thing. It is still just G-code, but one of the less recognized dialects. I guess finding a post processor that fully recognizes DX-32 is not so easy (and will cost you). Also, the on-board program space is quite limited. So far this has not been a problem for me, because I’m G-coding directly (either from the terminal or with CNC-CookBook’s editor). I would like to get into building the solid model and programming the tool path (one can “drip feed” the program – I have not figured that out) - so I'm not using any CAM program. I played around with F360, and a bunch of Titan's tutorials, but have found it works well to just type in your own code (I've been doing simple stuff, and it is still a game changer).

Coming from an all manual guy – the machine is awesome. The G-code library is extremely capable – just coding directly makes the majority of conventional mill tasks a dream.

I suppose everyone has a different story of how they got into CNC. I went with an old commercial machine and have been very satisfied. Apparently you can get full on system upgrades, but it isn't cheap. Probably one could do their own upgrade - but hey, it works great (probably pretty well as good as it did 20 years ago), so I'm just using it. I have made internal/external hex shapes, I made two sets of replacement 2 piece jaws for a 12"3J that I use on the mill table (generating those scroll teeth is one line of code for each face, followed by a translation, repeated 8 times), large circles (arcs), drills holes really nice, . . . I'm a believer now. Enjoy, David

The hobby CNC mills seem fine, still not cheap and my other machines are commercial grade and decent size, so I could see I'd be wanting more. I'm very impressed by the conversion machines people build, but that felt quite daunting (much more to learn and really a lot of work to approach the features of a commercial machine). A full on commercial VMC came available right in my "neck of the woods". So I went and checked it out, 1998 Bridgeport VMC 1000, 4 axis, #40 taper, 22 tool changer, full enclosure, flood coolant, chip conveyor - connected and running. It even came with a bunch of tools. Well, it was "way too big for me", I would need to upgrade my little 5HP RPC, the rough price range was out of my league – the self rationalization not to get it continued (more power and features than I needed) and I walked away. I was still wanting to learn the market, so I did a follow up call 10 months later to find out what it sold for – apparently I was the only one who had inquired and the owner just wanted it gone. Strictly speaking an old CNC, even if it works like day #1 – has no commercial value (he was getting rid of it because of difficulties in keeping staff current, the new CNC machines are much more productive and easier to use, there were numerous minor issues) – as another business isn’t going to buy it (they would have all the same issues) and it is too much for a hobby guy. That makes the candidate ma

Humm, maybe all that capability wouldn’t be such a bad thing after all? It still cost some real money (per my bank account – but for a real machine it was crazy cheap). A condition of the purchase was to use an insured, industrial machinery mover to get it out of the building. It was not in a difficult location, but the owner was not going to tie up his guys or risk any of his other equipment with some armatures mucking around. The movers mobilized out of Calgary, pickup, kneel down low bed, #30,000 rated forklift – and $2500 later the job was done. In retrospect, paying for the move was a good deal. I’ve move several smaller regular machines (2000-3000 pounds) – but these guys did not rush, worked very safe, nothing anywhere was even scratched – and were totally done, start to finish in 4½ hours. Simply part of the cost of the machine.

The machine dominates my shop, but it has really grown on me. The power requirement rationalized a PhasePerfect (the PP cost as much as the machine plus the moving cost) – I should have bought the PP before, all the machines really like it. I certainly don’t regret, “too much power and too many features”.

At first I was scared of the antique electronics. Well, so far so good. The floppy drive converter turned out to be a configuration issue. The mystery lock ups of the MMI (man machine interface) may have been due to me connecting the 240V power where the shop had it hooked up (they were on 208V). I replaced the MMI computer, which is simply a Pentium on a half card board with a newer one from Aliexpress. That took some research, but others have been down that path (BP made quite a few VMCs in this or similar models) – apparently many equipment makers in various industries used PC based controls, so you can get a newer one quite easily. The tool changer did not index properly and I snapped a few gripper fingers. That turned out to be a configuration / power issue – and new grippers are still available (it seems this is a fairly common problem).

I have included a picture of the old board (the "Dallas" chip has the battery imbedded in it).

The machine was pretty clean – until I took the guards and covers off. I spent about a month cleaning. The tooling is BT40, and it was an odd-ball mix – so I’ve been purchasing the odd piece here and there. At new pricing, the tooling would have cost more than what I paid for the machine.

One challenge is that the controller is DX-32. Apparently it was a Bridgeport thing. It is still just G-code, but one of the less recognized dialects. I guess finding a post processor that fully recognizes DX-32 is not so easy (and will cost you). Also, the on-board program space is quite limited. So far this has not been a problem for me, because I’m G-coding directly (either from the terminal or with CNC-CookBook’s editor). I would like to get into building the solid model and programming the tool path (one can “drip feed” the program – I have not figured that out) - so I'm not using any CAM program. I played around with F360, and a bunch of Titan's tutorials, but have found it works well to just type in your own code (I've been doing simple stuff, and it is still a game changer).

Coming from an all manual guy – the machine is awesome. The G-code library is extremely capable – just coding directly makes the majority of conventional mill tasks a dream.

I suppose everyone has a different story of how they got into CNC. I went with an old commercial machine and have been very satisfied. Apparently you can get full on system upgrades, but it isn't cheap. Probably one could do their own upgrade - but hey, it works great (probably pretty well as good as it did 20 years ago), so I'm just using it. I have made internal/external hex shapes, I made two sets of replacement 2 piece jaws for a 12"3J that I use on the mill table (generating those scroll teeth is one line of code for each face, followed by a translation, repeated 8 times), large circles (arcs), drills holes really nice, . . . I'm a believer now. Enjoy, David