I'm asking the question here because it's more about how to use my lathe than about the specific project.

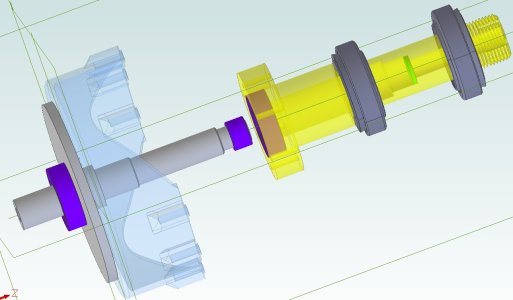

The yellow drive spindle is held in two tapered roller bearings and turns at 1/36th of the grey drive shaft. The purple bearings hold the drive shaft centered in the yellow spindle. The small green disk inside the spindle is pressed in but can, from the threaded end be pressed out pushing the needle pilot bearing with it.

The question is how to bore the 16mm hole for the pilot bearing. It's 70mm down inside the spindle. The relief hole in front of the 16mm hole is 20mm diameter while the spindle itself is 25.4mm outside diameter.

I'm thinking that if the spindle is held in either a collet or 4-Jaw and centered that boring it with an oversize custom boring bar to say 15.5mm and then reaming with a 16mm reamer will create a concentric with the OD hole.

I'd also bore the 35mm hole for the ball bearing at the bottom of the spindle at the same time.

Does that all make sense?

Should I even bother with a reamer?

The yellow drive spindle is held in two tapered roller bearings and turns at 1/36th of the grey drive shaft. The purple bearings hold the drive shaft centered in the yellow spindle. The small green disk inside the spindle is pressed in but can, from the threaded end be pressed out pushing the needle pilot bearing with it.

The question is how to bore the 16mm hole for the pilot bearing. It's 70mm down inside the spindle. The relief hole in front of the 16mm hole is 20mm diameter while the spindle itself is 25.4mm outside diameter.

I'm thinking that if the spindle is held in either a collet or 4-Jaw and centered that boring it with an oversize custom boring bar to say 15.5mm and then reaming with a 16mm reamer will create a concentric with the OD hole.

I'd also bore the 35mm hole for the ball bearing at the bottom of the spindle at the same time.

Does that all make sense?

Should I even bother with a reamer?