Anybody ever tell you that you have a stubborn streak?

So please in the interest of retaining your employment please reconsider the ask in post # 1 and kindly stay within the confines of the parameters as set out.

Yup, just like every other great corporation, Johnny Blocks has been hog tied by the finance department and will surely fail.....

Management is too stubborn and has no clue about the reason why we have lathes.

But as per the request from the sales department.

Work flow, tool holding, order of operations, potential unseen problems etc.

Tools at hand,

Gorton knee mill,

News rotary table,

Narex boring head,

Accurite DRO,

new end mill.

All of it is in good shape.

Tooling assessment by machining department.

We can do it, but we need a raise. And somebody please fire the finance department and send management to a conference on proper management of skilled staff.

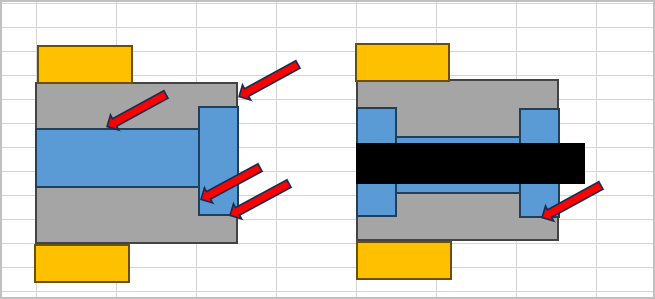

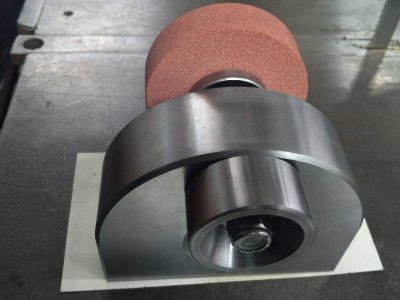

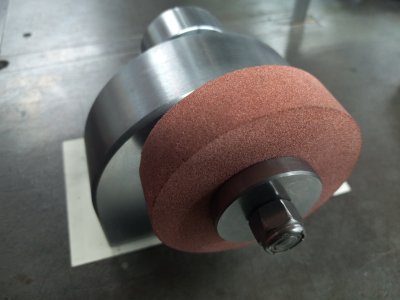

Job - Block of 1 1/2" steel needs a clearance through hole, with a counter bore on either side for bearings to press in and run concentric with each other.

Use some crap steel to make a vise stop since its not on your tooling list.

Write a work order to have the mill trammed by competent maintenance staff.

Have a few cups of Joe, ask your team how they enjoyed their weekend off, and then get to work! Gotta be done before management returns.

True the block, and make registration surfaces on the block so it can be flipped and maintain alignment. If you don't do this,

The opposite counter bore was way out of line.

Zero the X & Y coordinates on your DRO at the registration surfaces.

Move the X&Y axis to the desired hole location and record or save the offsets.

Make sure you include enough clearance for the hole web.

Drill the through hole.

Use the Narex Boring head to bore the top side bearing recess.

Flip the block against the registers.

Touch off the X coordinate register and rezero.

Move the x axis to the previous offset and then bore the opposite side bearing recess.

Alternative Assessments.

Rotary table - too much fiddling to clamp parts, find center, create registration surfaces, and clamp adequately. Probably a good time to oil it though......

Lathe - a total waste of money sitting there unused when it would have been sooooo easy to make a bushing. I'd ask the accounting and assets department to sell it or at least hire somebody who knows how to make bushings.

Hopefully management has returned home with a new appreciation for the guys who do all the work that they can't do. And don't eat at the joint where the finance guys are flipping burgers now.

Round of applause for the machining department please!