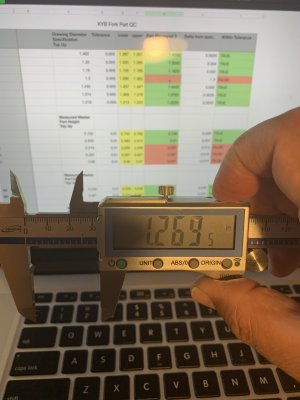

Anybody have a bluetooth digital caliper for recording measurements into your computer? Or maybe the USB kind?

iGaging has a bluetooth model and I'm wondering what people think of it? $65USD with shipping. I imagine mitutoyo has something too. Probably out of my price range. Is bluetooth type reliable? Or would I actually want a wired one?

https://www.amazon.com/iGaging-Elec...words=igaging+bluetooth&qid=1625785773&sr=8-1

iGaging has a bluetooth model and I'm wondering what people think of it? $65USD with shipping. I imagine mitutoyo has something too. Probably out of my price range. Is bluetooth type reliable? Or would I actually want a wired one?

https://www.amazon.com/iGaging-Elec...words=igaging+bluetooth&qid=1625785773&sr=8-1