-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

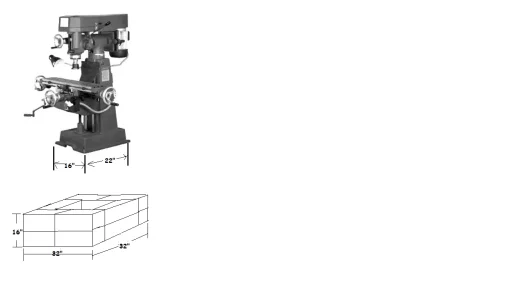

Base for a small (6 x 26) Knee Mill

- Thread starter doogymon

- Start date

Hi

Can a guy (or a Gal) build a base out of concrete?

Or cinder blocks?

Cheers & thanks.

Doog

Gals can but guys can't......

Jk!

If a mill can sit on a steel stand that can sit on concrete, then the steel stand in between is not needed. That's MHO.

The big mills all sit on concrete - just floor level.

Seriously, I see no reason why not other than you won't be moving that around very easily.

Former Member

Guest

Cinder blocks  don't!

don't!

Concrete why?

Steel frame or heavy duty cabinet is more than enough. What you have is a mill is similar to mine, though mine came with a cabinet and chip catch.

Ask some one to weld you up a frame. Likely cheaper and more versatile as you and store stuff underneath it.

Concrete why?

Steel frame or heavy duty cabinet is more than enough. What you have is a mill is similar to mine, though mine came with a cabinet and chip catch.

Ask some one to weld you up a frame. Likely cheaper and more versatile as you and store stuff underneath it.

Cinder blocksdon't!

Concrete why?

Steel frame or heavy duty cabinet is more than enough. What you have is a mill is similar to mine, though mine came with a cabinet and chip catch.

Ask some one to weld you up a frame. Likely cheaper and more versatile as you and store stuff underneath it.

@doogymon, I agree with @Degen and wouldn't use concrete for my own stuff either. But I really don't see any reason to say that it would not work. Blocks alone would probably be fine, but I'd fill them to absorb vibrations.

The big huge issue is that you won't be moving a concrete base once it's made. A steel frame is infinitely more useful and plenty strong enough.

So I gotta ask the question - Why do you want to use concrete anyway?

Former Member

Guest

Blocks crack under vibration and will pull your anchors.

What about wood gents as an alternative? I know it is not recommended but... it's inexpensive, easy ? Perhaps using a lot of wood 4x4 screwed and glued together. Diagonal bracing..? My small machines are on wooden benches, occasionally I have to tighten the bolts.

Blocks crack under vibration and will pull your anchors.

Not if they are filled. Think of them as a handy form. They actually work great. Concrete is a wonderful vibration absorber.

Again, not what I would do but certainly no reason why not.

What about wood gents as an alternative? I know it is not recommended but... it's inexpensive, easy ? Perhaps using a lot of wood 4x4 screwed and glued together. Diagonal bracing..? My small machines are on wooden benches, occasionally I have to tighten the bolts.

No reason why not. Wood is often the forgotten material. I use it for lots of things.

Was just kicking the idea around

I have a bunch of cinder blocks on hand.

I welded a steel table for my Mill/Drill and it's not as rigid as I'd like. Could shore it up.

Steel is kind of expensive right now.

Cast Iron is the ultimate i think.

The factory stands seems a little light unless you stumble upon an old school one.

I have a wooden lathe bench (12 x 36)....works lovely but wood is thru the roof even though our Canada is loaded...lol

I have an idea on how to clamp the blocks together so that I coul dismantle if moving. Would load the pockets with something.

I like sailor proof stuff.

The wee mill is a sit down jobbie right now.

Thanks

Doog

I have a bunch of cinder blocks on hand.

I welded a steel table for my Mill/Drill and it's not as rigid as I'd like. Could shore it up.

Steel is kind of expensive right now.

Cast Iron is the ultimate i think.

The factory stands seems a little light unless you stumble upon an old school one.

I have a wooden lathe bench (12 x 36)....works lovely but wood is thru the roof even though our Canada is loaded...lol

I have an idea on how to clamp the blocks together so that I coul dismantle if moving. Would load the pockets with something.

I like sailor proof stuff.

The wee mill is a sit down jobbie right now.

Thanks

Doog

Was just kicking the idea around

I have a bunch of cinder blocks on hand.

I welded a steel table for my Mill/Drill and it's not as rigid as I'd like. Could shore it up.

Steel is kind of expensive right now.

Cast Iron is the ultimate i think.

The factory stands seems a little light unless you stumble upon an old school one.

I have a wooden lathe bench (12 x 36)....works lovely but wood is thru the roof even though our Canada is loaded...lol

I have an idea on how to clamp the blocks together so that I coul dismantle if moving. Would load the pockets with something.

I like sailor proof stuff.

The wee mill is a sit down jobbie right now.

Thanks

Doog

You have nothing to lose for trying. A heavy wood top on blocks might be awesome. Nobody will know for sure till someone tries it.