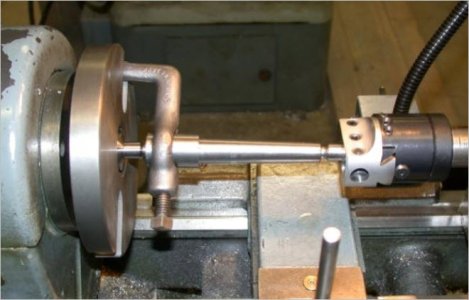

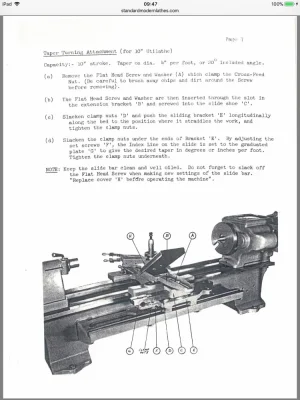

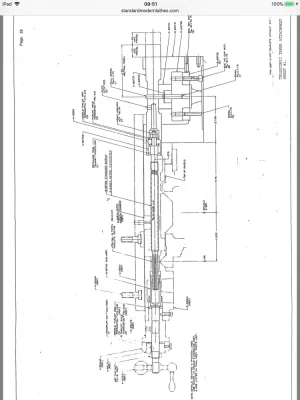

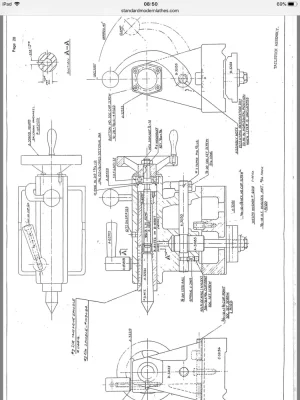

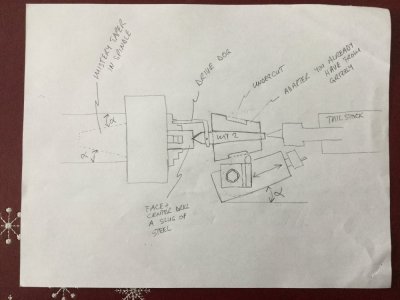

At the last meet-up at Modern Tool I was talking to someone (my apologies, forgot name) about cutting tapers using stock supported by ball ends when you don't have a taper attachment. I first saw this method in a model engineering magazine on a Myford lathe & the guy made all sorts of tapered shank tooling. The idea is you can leave your tailstock in its zero axial position & insert a device into tailstock that does the requisite offset similar to attached pic. Also you don't have to buy special center drills with curved profile meant to facilitate problem of 60-deg dead center running offset in 60-deg countersink.

I found some pics using a boring head which to my simple mind seems a lot easier than a separate, dedicated attachment. I'll admit some of those setups make me a bit squeamish, especially the high angle one. But maybe (hopefully) using shallow cuts....

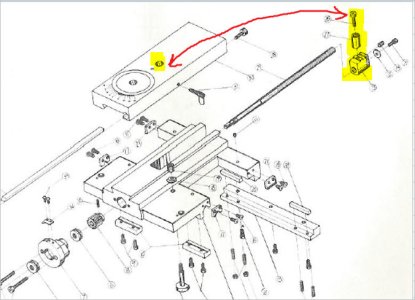

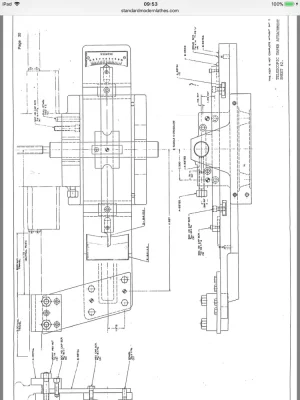

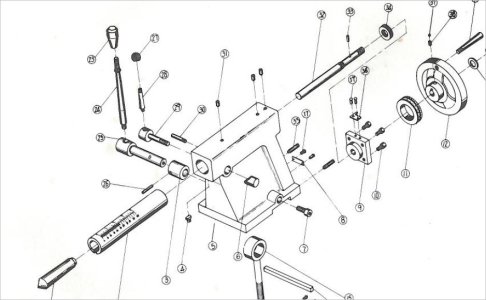

Anyway, I got thinking about how to A) orient the tailstock device so its in center plane and B) but then also prevent rotation in tailstock barrel? Most of the MT3 boring head arbors don't have a tang like a drill arbor. I think if they are intended for a mill they have threaded end for drawbar? I see the occasional one like this. I guess the trick is find one that has correct threads for boring head & yet extended/tang on taper end.

http://pacifictoolandgauge.com/ream...taper-3-mt3-boring-head-arbor-7-8-20-tpi.html

But getting back to A), once you screw in the boring head to the arbor, you have no control how the head center will line up to the tang. On a drill we don't care, it just resists motion. But here we need the dovetail to act horizontally. I cant figure out how guys do this?

Anyone mess around with setups like this?

I found some pics using a boring head which to my simple mind seems a lot easier than a separate, dedicated attachment. I'll admit some of those setups make me a bit squeamish, especially the high angle one. But maybe (hopefully) using shallow cuts....

Anyway, I got thinking about how to A) orient the tailstock device so its in center plane and B) but then also prevent rotation in tailstock barrel? Most of the MT3 boring head arbors don't have a tang like a drill arbor. I think if they are intended for a mill they have threaded end for drawbar? I see the occasional one like this. I guess the trick is find one that has correct threads for boring head & yet extended/tang on taper end.

http://pacifictoolandgauge.com/ream...taper-3-mt3-boring-head-arbor-7-8-20-tpi.html

But getting back to A), once you screw in the boring head to the arbor, you have no control how the head center will line up to the tang. On a drill we don't care, it just resists motion. But here we need the dovetail to act horizontally. I cant figure out how guys do this?

Anyone mess around with setups like this?