painly

Member

Hello all.

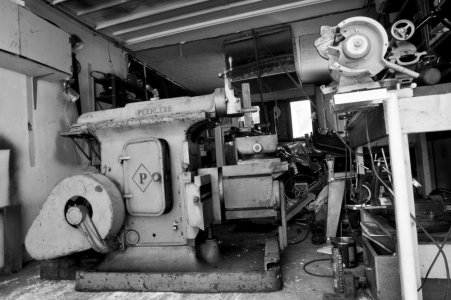

My name is Barret Russell and I reside in Saskatoon Sk. The home of almost no good used machinery! ha. Actually, I hitch hiked back from Toronto with an SB 9a about 15 years ago; but that's another story. My involvement in fabrication started in my early teens when I bought a MIG welder and started making lowrider bicycles, then in highschool started working on cars. Took a hiatus for uni and then in my late 20's became a bicycle frame fabricator. I built all my own jigging and to do this I owned a Peerless 18in shaper, Cincinnati 2mh, Sb 9a, and some other peripheral equipment for machining. I really enjoyed bike building but it was a hobby that never took off into a real paycheck. I also did my own paint. In those 5 years, I made maybe 30 frames and forks. I went back to school for a BSN and along with a few moves, lost the mill and shaper, rotary table, frame jig, and a good lot of scrap metal I'd been dragging around. Now, settled into nursing, and wanting to get my hands dirty, I have started to watch more and more machining videos and daydreaming of projects...still mostly bicycle related. I bought a little x2 sieg mini mill as it popped up locally, a 4in vise, and a 4in rotary table last month. My first project is a spindle for an electric bike motor pack. I broke the original while traveling down a mountain at 50kmh. This spindle may also force me to build a small oven...that's for another topic as well. It feels good to have a mill again to complement my little lathe, and albeit small, I am more than content with tiny cuts for my tiny parts I intend to make for my tiny projects. I also have a stepper motor and controller on order to turn the RT into an arduino controlled machine to act double duty as a dividing head and welding RT.

Anyways, thanks for the awesome forum! it has been fun lurking and I look forward in participating.

Barrett

My name is Barret Russell and I reside in Saskatoon Sk. The home of almost no good used machinery! ha. Actually, I hitch hiked back from Toronto with an SB 9a about 15 years ago; but that's another story. My involvement in fabrication started in my early teens when I bought a MIG welder and started making lowrider bicycles, then in highschool started working on cars. Took a hiatus for uni and then in my late 20's became a bicycle frame fabricator. I built all my own jigging and to do this I owned a Peerless 18in shaper, Cincinnati 2mh, Sb 9a, and some other peripheral equipment for machining. I really enjoyed bike building but it was a hobby that never took off into a real paycheck. I also did my own paint. In those 5 years, I made maybe 30 frames and forks. I went back to school for a BSN and along with a few moves, lost the mill and shaper, rotary table, frame jig, and a good lot of scrap metal I'd been dragging around. Now, settled into nursing, and wanting to get my hands dirty, I have started to watch more and more machining videos and daydreaming of projects...still mostly bicycle related. I bought a little x2 sieg mini mill as it popped up locally, a 4in vise, and a 4in rotary table last month. My first project is a spindle for an electric bike motor pack. I broke the original while traveling down a mountain at 50kmh. This spindle may also force me to build a small oven...that's for another topic as well. It feels good to have a mill again to complement my little lathe, and albeit small, I am more than content with tiny cuts for my tiny parts I intend to make for my tiny projects. I also have a stepper motor and controller on order to turn the RT into an arduino controlled machine to act double duty as a dividing head and welding RT.

Anyways, thanks for the awesome forum! it has been fun lurking and I look forward in participating.

Barrett