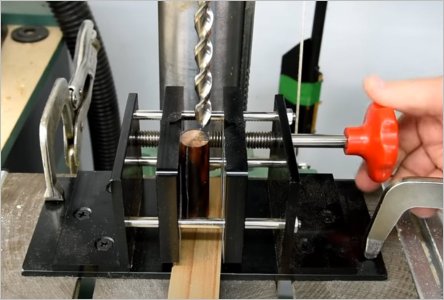

So I ran into a guy I know marginally at Princess Auto this AM. He's a British ex-pat and I've run in to him occasionally at toolstores and metal yards over the years. We chatted for a while, and the conversation ended up in the parking lot. He showed me a special drill press vice he just imported from England—and boy was it cool. It has a cam lever on it that, when released, allows about an 1/4" play in two planes. Once the cam is locked, it acts as a regular drill press vice.

The idea is the vice is clamped down, and assuming you have drilled a pilot hole, you release the cam so that when the larger bit is fed into the pilot hole, it self-centers in the hole because there is play in the vice. Once you are certain the bit is centered, you engage the cam and the bit follows that path precisely.

I was always taught this is the proper way to drill large holes on a drill press: punch or drill an appropriate sized pilot hole, don't clamp down the vice, let the bit "center" itself, turn off the drill press w/o releasing the down feed, and clamp the vice. Then finish your hole. This can be tricky as you only have one hand to work with, but works well if you prepare your clamps ahead of time. You certainly get more accurate holes this way.

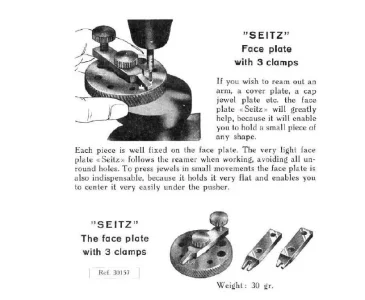

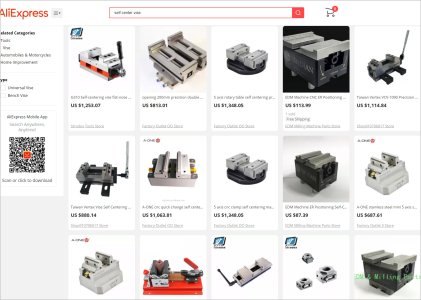

The vise he showed me make it much easier, but darned if I can find anything online. He called it a "wiggle" vise, I guess kind of like a Wiggler you'd use on a mill. His looked pretty pricey and high end. I don't think I'd spring for one, but was interested in looking them up nonetheless. However, I can't find one anywhere online. I wish I'd taken a pic or asked for more details. Great idea.

Has anyone heard of these or know their real name/manufacturer?

The idea is the vice is clamped down, and assuming you have drilled a pilot hole, you release the cam so that when the larger bit is fed into the pilot hole, it self-centers in the hole because there is play in the vice. Once you are certain the bit is centered, you engage the cam and the bit follows that path precisely.

I was always taught this is the proper way to drill large holes on a drill press: punch or drill an appropriate sized pilot hole, don't clamp down the vice, let the bit "center" itself, turn off the drill press w/o releasing the down feed, and clamp the vice. Then finish your hole. This can be tricky as you only have one hand to work with, but works well if you prepare your clamps ahead of time. You certainly get more accurate holes this way.

The vise he showed me make it much easier, but darned if I can find anything online. He called it a "wiggle" vise, I guess kind of like a Wiggler you'd use on a mill. His looked pretty pricey and high end. I don't think I'd spring for one, but was interested in looking them up nonetheless. However, I can't find one anywhere online. I wish I'd taken a pic or asked for more details. Great idea.

Has anyone heard of these or know their real name/manufacturer?