-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone fabricate Excello 602 riser?

- Thread starter Buffdan

- Start date

Anyone here fabricate one, or have dimensions?

I can only speculate about your needs. I suspect that the XLO base is similar to a Bridgeport. It certainly looks like it in the photos I looked at. If so consider buying a Bridgeport Riser after taking a few measurements. Or maybe just adapt one.

Reach out to @LenVW who used to work for Excello. He might be familiar with the dimensional differences.

If I had your problem, I'd either make one from thick walled pipe or perhaps a solid block - there is no reason it has to be hollow that I know of. It wouldn't be rocket science to get the dimensions from my own machine and I'm pretty certain that they are not critical. I might machine most of it on my lathe. I make similar things all the time to repair farm machinery.

In fact, you could probably make it out of four thick plates that would end up being 4 columns. These could even be welded or bolted together if it isn't rigid enough for your needs. I wouldn't think it needs to look special as long as it is rigid and dimensionally correct.

I'd also suggest you google Bridgeport Riser. Maybe even start with XLO Riser. I got plenty of hits on my end. That's how I found the riser I linked above.

FWIW, I might even visit a farm machinery yard and look for a tractor wheel coupling or axle extension close to the right size. There is probably a size that could be adapted.

great feedback, thank you. I've been looking locally for suitable material.

Saw some on ebay.. but shipping out of line..

Thanks!

There are farm equipment places all over the world. Prolly be one within driving distance. They often have steel stock too. You would be shocked to see the range of steel stock used to make farm machinery.

I’ve got one I pulled out of our First mill at work, happy to take some photos and dimensions tomorrow.

I’ve got one I pulled out of our First mill at work, happy to take some photos and dimensions tomorrow.

It would be good to know if the First, XLO, and Bridgeports are the same size. I should have measured mine when I had it apart. Sadly, too soon old and too late smart. Maybe I can measure it while it is assembled.

Buffdan

Member

Thank you Stelios... DanHere is a photo of the riser in the owners manual. If you need a clearer photo, I can scan it, and send you a copy.

Last edited:

I’ve got one I pulled out of our First mill at work, happy to take some photos and dimensions

First photo, right side up, overview. 15” outside diameter, 12 7/16” inside.

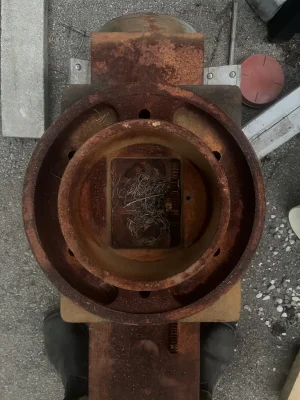

Second photo shows interior, the shelf for the upper spider to rest on is a nice touch, I was working hard to avoid dropping it, in the end unnecessary.

Third photo, upside down. 15” diameter, 4” high plus ~1/4” lip 12 7/16” diameter. Relief cut next to the lip.

Fourth photo, spider. Raised contact pads, other than the thread they’re the only machined surface.

I would be cautious about trying to slap some First mill components onto non-metric country of origin mills. While they’re clearly a Bridgeport clone, and mostly use North American hardware, there are oddball things like 1/4-20 screws with metric drive sockets (I’m sure, checked it twice) in our machine. I wouldn’t be at all surprised to find some metric threaded holes.

I would be cautious about trying to slap some First mill components onto non-metric country of origin mills.

This is the point I made earlier. I think all these clones are great machines. But mine (a Hartford clone of the Bridgeport Pulley Drive) has a number of non-clone parts in it. For example the main backgear belt has different cog spacing, and the back gear cover uses different size alignment pins. Yes, generally they are almost the same but you can't assume that is universally true.

In the plus side, the First is a heavier more rigid machine. And my Hartford has a Mehanite Table and Saddle.

Just take the good where you find it and accept the bad. These clones are all pretty darn good machines!

Second photo shows interior, the shelf for the upper spider to rest on is a nice touch, I was working hard to avoid dropping it, in the end unnecessary.

Mine has that feature too. However the previous owner dropped the spider inside despite that and broke one of the arms off. They re-used the spider with just three arms. I thought the one bolt was stripped till I took the ram off and saw the broken spider. The broken piece was still inside. The spider was the same as the Bridgeport Spider and wasn't too expensive.

I've never seen a document that describes the right way to align those tabs and take off the spider. I'll bet it exists though.

Buffdan

Member

Thank you Stuart.. Much appreciated!!View attachment 50229View attachment 50230View attachment 50231View attachment 50232

First photo, right side up, overview. 15” outside diameter, 12 7/16” inside.

Second photo shows interior, the shelf for the upper spider to rest on is a nice touch, I was working hard to avoid dropping it, in the end unnecessary.

Third photo, upside down. 15” diameter, 4” high plus ~1/4” lip 12 7/16” diameter. Relief cut next to the lip.

Fourth photo, spider. Raised contact pads, other than the thread they’re the only machined surface.

Dan

You are absolutely correct about the metric headed fasteners on the First, mine anyhow. It also uses an m6 dog point set screw as the R8 key in the spindle so there are metric fasteners in the mix too.I would be cautious about trying to slap some First mill components onto non-metric country of origin mills. While they’re clearly a Bridgeport clone, and mostly use North American hardware, there are oddball things like 1/4-20 screws with metric drive sockets (I’m sure, checked it twice) in our machine. I wouldn’t be at all surprised to find some metric threaded holes.

None of this is a problem as long as you don’t forget…….

D.

Hey Dan! If a Bridgeport riser is compatible, there’s one down near Windsor for $150!

www.facebook.com

www.facebook.com

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

that is so tempting.. great price.. About 4 hour drive one way..

I bet it wont last long.

hmmmmm.

Thanks for thinking of me Stuart

I think it will last longer than one might otherwise suspect.

Essex is just an hour for me. If you swing a deal with the seller, I could go get it today or tomorrow and stop in at a friend's too. Then you can get it here at your convenience. If Essex is 4 hours for you, I'm prolly 3. Depending on where you are, there might be a few other members you could drive with and then we could make it a meetup. Lots of ways to make it work..

Let me know.

Rauce

Ultra Member

Here’s the piece that a riser would sit under on my old machine. I don’t have the column anymore (scrapped).

14.75” OD, 6 holes on a 10.5” PCD and a spigot just inside the bolt circle at 9.5”.

Going off memory, I think there’s two half rings that the bolts thread into that clamp it down.

14.75” OD, 6 holes on a 10.5” PCD and a spigot just inside the bolt circle at 9.5”.

Going off memory, I think there’s two half rings that the bolts thread into that clamp it down.