it appears as there are 2 spots for extra gears

Sorry, what do you mean by that?

From the posted pictures, you have 4 places total where you can put gears. I labelled them for you 1-4.

The best way for us to help you is if you take a black sharpe and write the # teeth right onto each gear in big numbers, install them and then take a picture.

Position 1 is the input. Right now it has a 38T gear on it. It meshes with the 30T gear (I believe it is hidden behind the 80T (maybe 90T - can’t really tell) gear in the other picture. Can you please confirm, thanks. If you put gears with different teeth count onto the same shaft and they are splined together, you have made a compound gear, whose ratio must be considered in calculating a gear train (together with the input gear and the output gear). Everything else is just a filler (position 2 & 3 - unless they are compounded) and can be disregarded. You probably already know that.

Position 4 is the output of the gear train (input shaft of the QCGB).

So, can you also show us a side view of you gear train (a sketch will suffice) like in this example:

In your case, I don’t expect to see a single row of gears as you have a compound set-up.

Where am I going with this? You may not be missing as many gears as you think you are. I am pretty sure that you need a 127T gear for your metric and module threads. It would take the place of the 120T gear you have in a compound set-up.

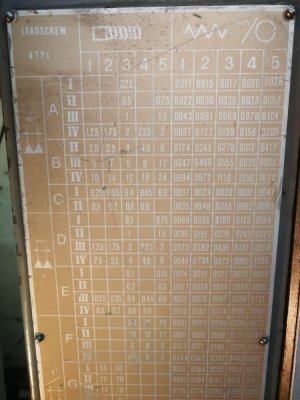

Question: have you actually threaded the pitches in the “F” portion of the table and measured them for accuracy? And what was your gear train set-up for that? The one you took a picture of?

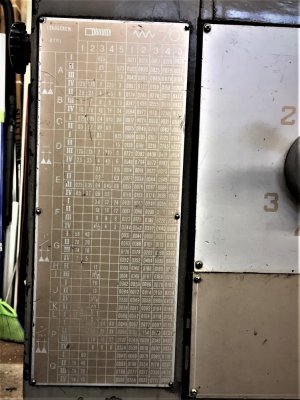

If the gear train is set-up properly (with the gears you have), you will get the accurate threads and the same feeds (inches/spindle rev) as the chart on your lathe under section “F” shows. From your actual feeds chart you posted above, you are not matching what the lathe says you are supposed to get. The gear train and / or QCGB is most likely not set correctly.