My welding skills would be 0.3 out of ten, but my business partner has asked me if I can help him with a small project. After upgrading his 36ft speedboat to twin 300HP Yamaha outboards, the attachment post for water skiers no longer clears the top of the outboards. (I know, the horror of first-world problems.)

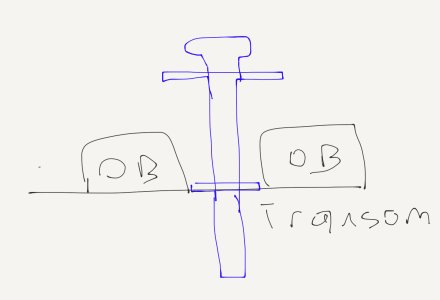

The request is to increase the distance between the two cross arms and the plate. The plate attaches to the top surface of the transom. The cross arms need to be 12” farther away to clear the outboards. The open end away from the cross arms is drilled and tapped in two places to bolt to a couple of angle brackets below the transom. The top is capped off with a 1/2” thick plate.

The problem is the post is bizarre. It’s fabricated from two pieces of aluminum pipe - 2” Sch40 sleeved inside 2-1/2” Sch40. The two pieces of pipe are welded at each end, with the cross arm as a single piece of 1” aluminum bar welded to the outside of the 2-1/2” pipe. So I can’t just cut and weld in a section, because it’s impossible to weld the inner pipe.

I‘m about 90% sure the manufacturer made up this kluge so they would have enough wall thickness to drill and tap, my math says adding the inner 2” pipe doesn‘t provide much extra strength.

So - try to cut it apart and do a multi-step staggered weld, or cut off the plate and just buy two new pieces of pipe and make a whole new post?

The request is to increase the distance between the two cross arms and the plate. The plate attaches to the top surface of the transom. The cross arms need to be 12” farther away to clear the outboards. The open end away from the cross arms is drilled and tapped in two places to bolt to a couple of angle brackets below the transom. The top is capped off with a 1/2” thick plate.

The problem is the post is bizarre. It’s fabricated from two pieces of aluminum pipe - 2” Sch40 sleeved inside 2-1/2” Sch40. The two pieces of pipe are welded at each end, with the cross arm as a single piece of 1” aluminum bar welded to the outside of the 2-1/2” pipe. So I can’t just cut and weld in a section, because it’s impossible to weld the inner pipe.

I‘m about 90% sure the manufacturer made up this kluge so they would have enough wall thickness to drill and tap, my math says adding the inner 2” pipe doesn‘t provide much extra strength.

So - try to cut it apart and do a multi-step staggered weld, or cut off the plate and just buy two new pieces of pipe and make a whole new post?