Matt-Aburg

Ultra Member

I have a lot of pure scrap aluminum. I am trying to find a method of compacting into about 2-3 inch diameter pucks. The purpose is to hopefully reduce air and oxidization for reclamation in the small propane foundry. I have seen only one video of a guy using a pop can to put the chips in and compacting with a stick. The melt time was excessive at 40 minutes. He was using a can for a crucible. The combination of not packing it tight and not having a proper crucible equals too much cost for fuel. I have attached the link.

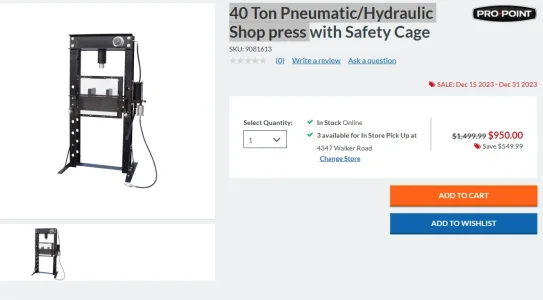

I am thinking of using a log splitter to compact the chips. My main question though is if that is enough force? It would be faster than a shop press. Looking now a log splitter from crappy tire ranges about 400 on sale for 9 tons. I would need to make modifications to it. This does seem risky if it is a failure, in that I have no wood to split....

Many have said that its the wrong kind of aluminum. It could be mixed with either the correct alloy, or adding silicon. also link attached.

So my questions are, has anyone tried to make briquettes for this purpose? Would I just be better off to curb the chips? I could try the idea in first video, to see if it is worth 400 dollars to pursue it.

I am thinking of using a log splitter to compact the chips. My main question though is if that is enough force? It would be faster than a shop press. Looking now a log splitter from crappy tire ranges about 400 on sale for 9 tons. I would need to make modifications to it. This does seem risky if it is a failure, in that I have no wood to split....

Many have said that its the wrong kind of aluminum. It could be mixed with either the correct alloy, or adding silicon. also link attached.

So my questions are, has anyone tried to make briquettes for this purpose? Would I just be better off to curb the chips? I could try the idea in first video, to see if it is worth 400 dollars to pursue it.

Last edited: