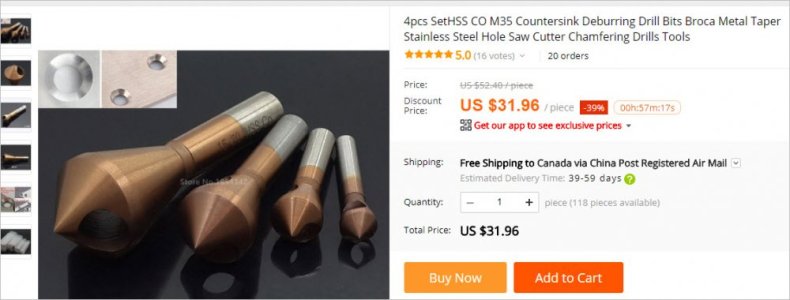

My AliExpress 90-deg chamfering cutters arrived & I must say I'm quite impressed with them. I struggle with the multi-flute cutters, even good quality ones. They seem to be very rpm & feed sensitive. Things go dandy for a while & then in a blink they can develop this harmonic & you get ugly bumpy path syndrome like looks like a ring of fine teeth which is then hard to remedy. On thin metal it can be even worse.

These (I guess you could call them 1-flute) cutters just seem to work with a lot more control. I had to do some very fiddly chamfering for M3 screw heads & I could control the chip right down to the thou. I'm not exactly sure how to sharpen them if you grind the whole body down, or if you can somehow dress the angled through hole which makes the cutting lip itself. They have some mystery coating that's kind of a bronze color, not like the gold TIN (or in some cases gold spray paint I swear LOL).

https://www.aliexpress.com/item/4pc...329.html?spm=a2g0s.9042311.0.0.3da24c4d5zrcg6

These (I guess you could call them 1-flute) cutters just seem to work with a lot more control. I had to do some very fiddly chamfering for M3 screw heads & I could control the chip right down to the thou. I'm not exactly sure how to sharpen them if you grind the whole body down, or if you can somehow dress the angled through hole which makes the cutting lip itself. They have some mystery coating that's kind of a bronze color, not like the gold TIN (or in some cases gold spray paint I swear LOL).

https://www.aliexpress.com/item/4pc...329.html?spm=a2g0s.9042311.0.0.3da24c4d5zrcg6