Hoping someone can give me a bit of a sanity check on my compressor fill time.

10.2 cfm @90 psi pump

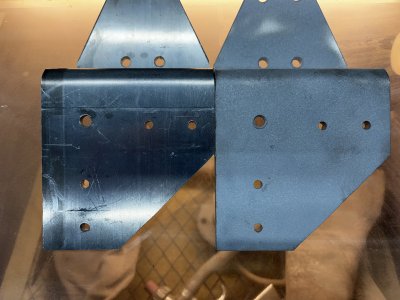

40 gallon tank (2x20 joined)

8 minute fill time from empty.

2 minutes to refill from 90 psi to 125 psi.

Does this seem reasonable?

10.2 cfm @90 psi pump

40 gallon tank (2x20 joined)

8 minute fill time from empty.

2 minutes to refill from 90 psi to 125 psi.

Does this seem reasonable?

Last edited: