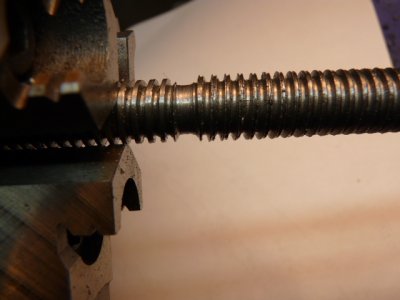

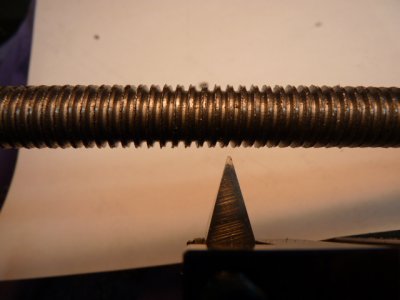

I'm practicing acme threading and am having an issue with cutting (or pushing) the material. I've done the usual searching of youtube and other sites but am coming up empty. The picture shows the problem where the metal seems to be pushing up rather than being cut cleanly. There is a lot of metal being cut as well but the ridges don't seem to go away and it starts being noticeable at about .025 deep and I'm only using a .002 DOC. The pushed material is proud of the rod so it can be trimmed to work but I don't think I should have to do that. I've reground the bit a few times to get the geometry to what I can find to be correct but something is still not right. The lathe isn't labouring or chattering so I don't think that's a problem. I do have a thread gage, not a Starrett but it seems to give the right shape. The steel is inexpensive CR if that would make a difference or not.

I need to get this right before ruining the 1144 rod that is coming.

There are lots of youtube how to thread videos out there but I don't find many "how to fix" threading problems videos.

All help is appreciated.

I need to get this right before ruining the 1144 rod that is coming.

There are lots of youtube how to thread videos out there but I don't find many "how to fix" threading problems videos.

All help is appreciated.

Attachments

Last edited: