MrBlair

Member

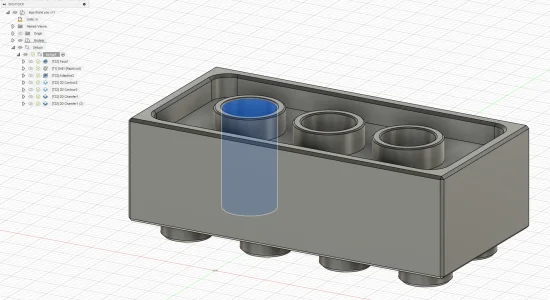

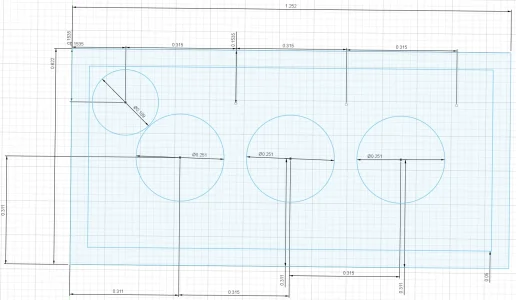

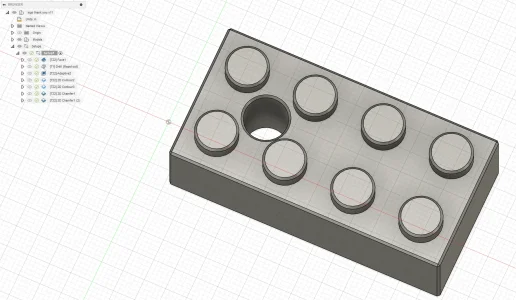

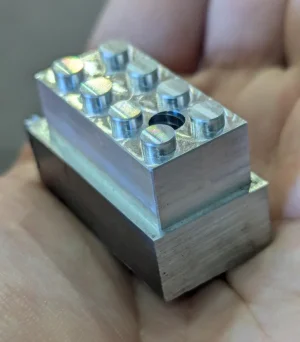

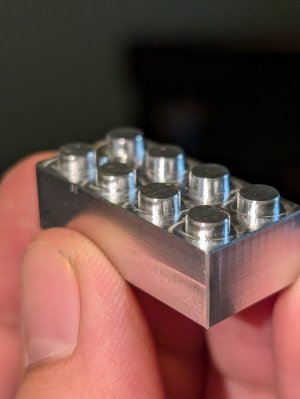

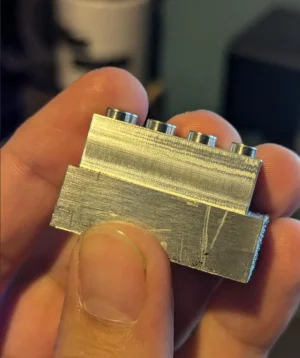

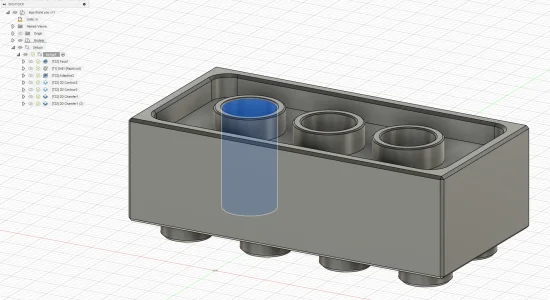

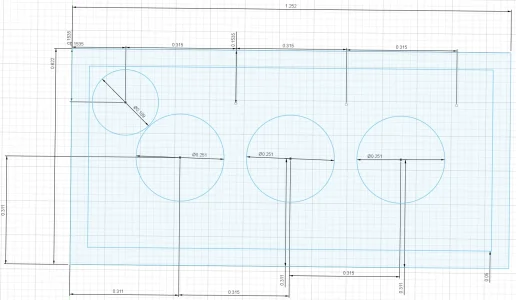

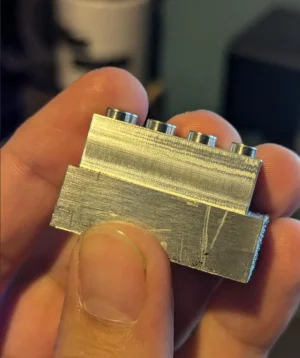

Hello everyone, I'm currently working on a thank you gift to a few coworkers + a tour gift to groups, a Lego piece. Currently finished the first operation, faces and contours the top and sides, cutting .02 lower than necessary to give extra breathing room for 2nd operation. (mostly happy with that, except for a weird abrasion mark on the finishing pass of the sides, using a 12111810 M.A. FORD 2 flute 3mm carbide and only removing .005).

The second operation has me a bit worried, chamfer around is .01 on the outer edge, and .005 on the inner cylinders, I'm worried that if I'm off by even a small amount it'll be rather noticeable. To help with indicating I plan to put a hole through one of the inner cylinders on the bottom, to help indicate from there. Am I overthinking it, would simply removing the excess stock, and then edge finding before removing the last .02 be all I need to do? Or would using an indicator holder and finding the center of the hole be the best solution, or what would you guys do?

The second operation has me a bit worried, chamfer around is .01 on the outer edge, and .005 on the inner cylinders, I'm worried that if I'm off by even a small amount it'll be rather noticeable. To help with indicating I plan to put a hole through one of the inner cylinders on the bottom, to help indicate from there. Am I overthinking it, would simply removing the excess stock, and then edge finding before removing the last .02 be all I need to do? Or would using an indicator holder and finding the center of the hole be the best solution, or what would you guys do?