Our Kitchen sink sprung a leak where the 1-1/2" drain pipe joins into the 4" sewer pipe. Basically, the 45 degree fitting that connects the two pipes broke in half. No idea why but it's the third Y pipe in the house to fail that way. If I had to guess I'd say a bad batch of Y-Pipes.

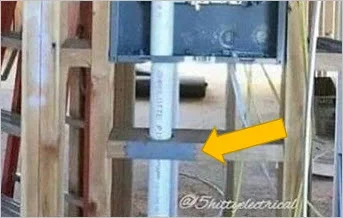

The other two were easy fixes. I just replaced the whole assembly. This one was not so easy. It broke above the ventilation ducts between joists. The only way to replace the assembly would be to drop the ventilation ducts. I didn't want to do that unless I had to.

So I cut the sink drain pipe out with a 12v reciprocating saw, and then had to remove the rest of the 45. I had thought that would be easy - just crack the glue apart. But as @Dabbler pointed out in a later conversation, the glue isn't really a glue. It fuses the two pipes together. Crap.

I took a step back and decided to cut the top layer off with a hole saw. Didn't work worth crap. Scratch that idea. I'd have used a smaller hole saw as a pilot inside the bigger hole saw but didn't have the right size.

The next thought was to make an annular cutter with a pilot to fit the inside pipe.

The idea was to use the pilot to follow the inside pipe and the cutter to remove the outside pipe by rotating it around the pipe.

The first iteration had a hose clamp holding the cutter to the pilot. Didn't hold. Should have known better.

The second was held in place by 8mm machine screws. That worked. Many guys on here would have welded the parts together. I prefer bolts cuz I can't weld worth crap.

I was in a bit of a hurry so I planned to just turn the unit by hand. If that didn't work I would have machined it to take a 1" socket. Actually it turned out that a pair of Knipex Cobras were needed once in a while but it did the job just fine. With the old 45 gone, I glued a new one in place and added a short extension so I could put a new coupler between rafters.

The scroll lines on the tool are the remnants of the threads on the 1.75" bolt I used to make the tool from. The cutter itself is just left over scrap metal from the motor adapter I made for my mill.

This is a very typical project for me. I regularly make custom tools to repair farm machinery or stuff around the yard and house.

Hopefully sharing the idea might come in handy for others some day.

The other two were easy fixes. I just replaced the whole assembly. This one was not so easy. It broke above the ventilation ducts between joists. The only way to replace the assembly would be to drop the ventilation ducts. I didn't want to do that unless I had to.

So I cut the sink drain pipe out with a 12v reciprocating saw, and then had to remove the rest of the 45. I had thought that would be easy - just crack the glue apart. But as @Dabbler pointed out in a later conversation, the glue isn't really a glue. It fuses the two pipes together. Crap.

I took a step back and decided to cut the top layer off with a hole saw. Didn't work worth crap. Scratch that idea. I'd have used a smaller hole saw as a pilot inside the bigger hole saw but didn't have the right size.

The next thought was to make an annular cutter with a pilot to fit the inside pipe.

The idea was to use the pilot to follow the inside pipe and the cutter to remove the outside pipe by rotating it around the pipe.

The first iteration had a hose clamp holding the cutter to the pilot. Didn't hold. Should have known better.

The second was held in place by 8mm machine screws. That worked. Many guys on here would have welded the parts together. I prefer bolts cuz I can't weld worth crap.

I was in a bit of a hurry so I planned to just turn the unit by hand. If that didn't work I would have machined it to take a 1" socket. Actually it turned out that a pair of Knipex Cobras were needed once in a while but it did the job just fine. With the old 45 gone, I glued a new one in place and added a short extension so I could put a new coupler between rafters.

The scroll lines on the tool are the remnants of the threads on the 1.75" bolt I used to make the tool from. The cutter itself is just left over scrap metal from the motor adapter I made for my mill.

This is a very typical project for me. I regularly make custom tools to repair farm machinery or stuff around the yard and house.

Hopefully sharing the idea might come in handy for others some day.