I thought you guys might like seeing this. I've been making a huge effort climbing the curve on resin printed patterns and then investment casting them (not quite there yet), Last weeked I diverted from that and did this this filament print casting in AL. Polycast filament, 16 hour burn out cycle, for casting, the mold at 400C, AL at 730C. It worked fairly well, that filament is awesome stuff and burned out perfectly. This would be a very difficult part to cast via the tradition two part mold with cores so it show the potential of investment casting. Its pretty neat the potential there is with this stuff.

There was some cracking of the investment, but that was my fault...hence the "mostly". It lead to a bit of flash, but 2 minutes of fettling took care of it. You are supposed to start the burnout 1-2 hours after the investment is poured, but life got in the way and it sat for a week. I did get a bit of porosity in one spot. Not sure why as I'm using an electric melter. I think the part will still work, but I need to figure out why.

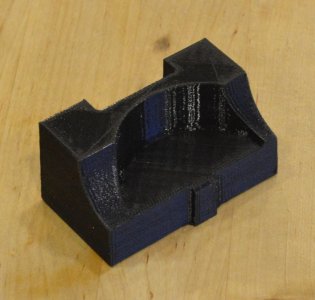

what is it? I need a vertical bandsaw for job so thought to adapt my horizontal band saw....this is a bracket to mount the mini table to the bandsaw frame

There was some cracking of the investment, but that was my fault...hence the "mostly". It lead to a bit of flash, but 2 minutes of fettling took care of it. You are supposed to start the burnout 1-2 hours after the investment is poured, but life got in the way and it sat for a week. I did get a bit of porosity in one spot. Not sure why as I'm using an electric melter. I think the part will still work, but I need to figure out why.

what is it? I need a vertical bandsaw for job so thought to adapt my horizontal band saw....this is a bracket to mount the mini table to the bandsaw frame