opensourcefan

OSF

Well, I wanted the ability to I decided to have some fun, do some learning and keep myself busy. I apologize in advance as I never meant to document the build for sharing so I don't have a lot of pics.

Here's a video, I'm not a camera-man nor a youtuber.

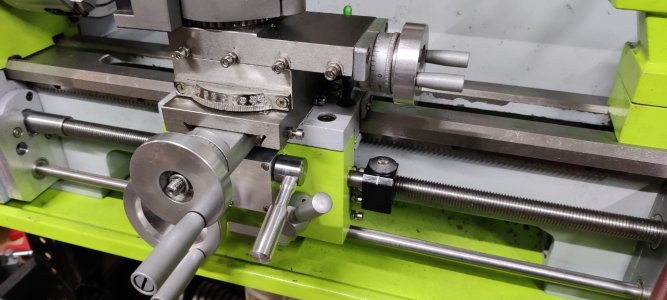

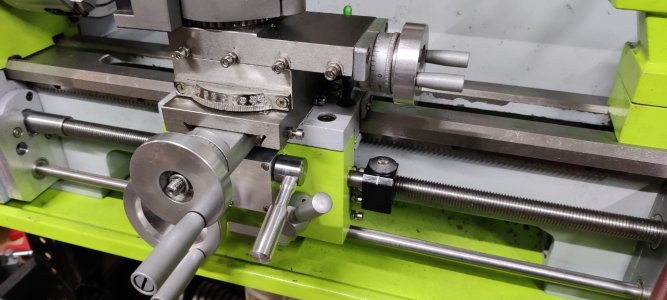

Here are some pics, just ask if you have any questions. I still have to build in my safety lockout to prevent both half nut and motor feeds being engaged at the same time. Some other little tweaks needed as well, but am happy that it all came together as planned.

Control

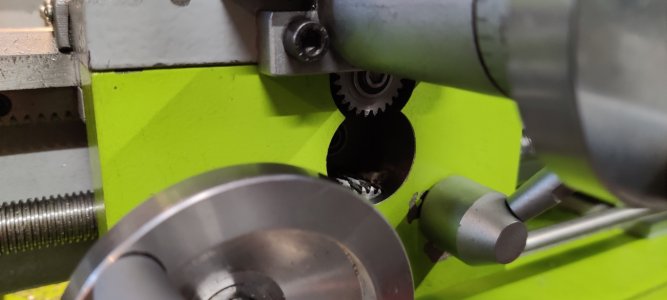

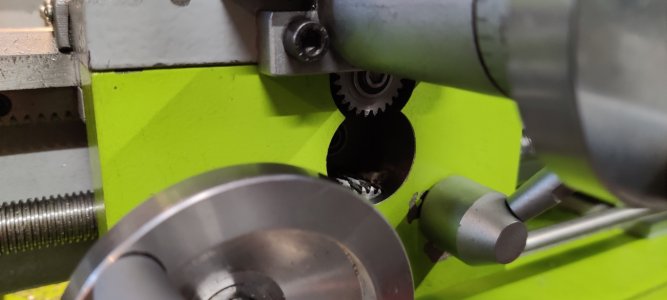

Inside the apron

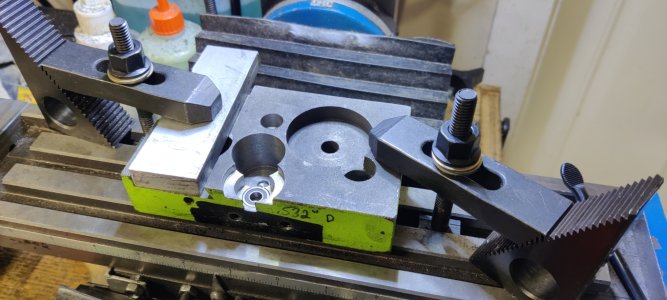

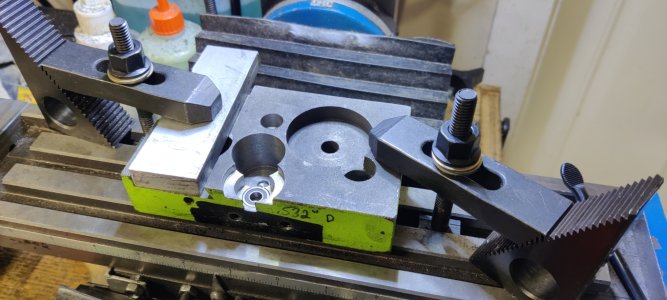

Apron being machined, gear pockets on both sides going up to the top

Saddle being machined. Was a tight fit in my little mini mill

The black box there is a 3d printed housing for an old 12v cordless drill motor that I've had for ever.

Motor is super old but thought I'd give it a try. It still has the planetary's attached for a good reduction in speed and increase in torque.

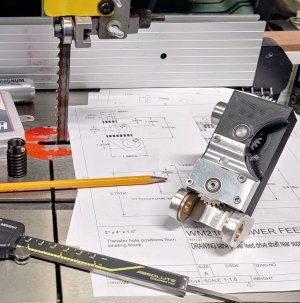

It's all using a 6mm wide belt and pulley setup. I made the belt tensioner assembly. That 12 point bolt is from a Bell 212 helicopter.

You can see the new bearing block, I was going to shape it to match the original but I'm kinda liking the big a$$ hunk of metal look.

Front bearing support, utilizing the original bolt holes underneath for the lead screw.

Main drive shaft and worm gear mount.

This pic shows the inboard side, again I apologize for the lack of photos here.

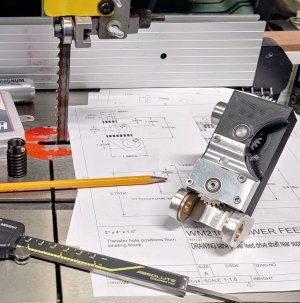

That's a 3d print of the apron section to test everything as I was going.

I used a full 1kg roll of filament going back and forth and testing this and that.

I had a lot of fun designing, drawing, machining etc. Kept my mind in check.

If you have questions just ask, I'm sure there is plenty that I didn't explain or cover.

Here's a video, I'm not a camera-man nor a youtuber.

Here are some pics, just ask if you have any questions. I still have to build in my safety lockout to prevent both half nut and motor feeds being engaged at the same time. Some other little tweaks needed as well, but am happy that it all came together as planned.

Control

Inside the apron

Apron being machined, gear pockets on both sides going up to the top

Saddle being machined. Was a tight fit in my little mini mill

The black box there is a 3d printed housing for an old 12v cordless drill motor that I've had for ever.

Motor is super old but thought I'd give it a try. It still has the planetary's attached for a good reduction in speed and increase in torque.

It's all using a 6mm wide belt and pulley setup. I made the belt tensioner assembly. That 12 point bolt is from a Bell 212 helicopter.

You can see the new bearing block, I was going to shape it to match the original but I'm kinda liking the big a$$ hunk of metal look.

Front bearing support, utilizing the original bolt holes underneath for the lead screw.

Main drive shaft and worm gear mount.

This pic shows the inboard side, again I apologize for the lack of photos here.

That's a 3d print of the apron section to test everything as I was going.

I used a full 1kg roll of filament going back and forth and testing this and that.

I had a lot of fun designing, drawing, machining etc. Kept my mind in check.

If you have questions just ask, I'm sure there is plenty that I didn't explain or cover.