I just received in the mail an 8" independent 4-Jaw chuck made by Buck in the US. Used, purchased from a guy in Quebec on Facebook Marketplace.

I have a 14" Pratt Burnerd which has served me well for the past 30 years, except it's getting too heavy to be lifting it up onto a wooden board on the lathe bed.

A while ago, I wanted to get a Bison or a Kitagawa, but at $2,000 new, I couldn't justify it. I decided at the time to get an Atlas 6" for around $500.00. And it worked well enough, though it's a little small for some stuff. And it's nowhere near as nice as my 3-jaw Bison.

So now I have this 8", tight as a drum, no indication of use on the jaw faces, made in the US, smooth as silk, perfectly sized chuck for my needs. $350.00 including shipping!!

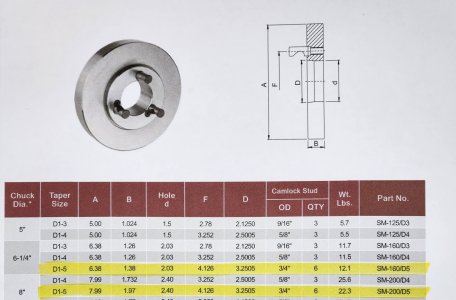

I now have to find an 8" D1-5 back plate to bolt it onto.

I have a 14" Pratt Burnerd which has served me well for the past 30 years, except it's getting too heavy to be lifting it up onto a wooden board on the lathe bed.

A while ago, I wanted to get a Bison or a Kitagawa, but at $2,000 new, I couldn't justify it. I decided at the time to get an Atlas 6" for around $500.00. And it worked well enough, though it's a little small for some stuff. And it's nowhere near as nice as my 3-jaw Bison.

So now I have this 8", tight as a drum, no indication of use on the jaw faces, made in the US, smooth as silk, perfectly sized chuck for my needs. $350.00 including shipping!!

I now have to find an 8" D1-5 back plate to bolt it onto.