Latest project:

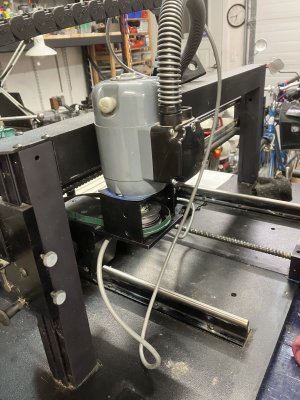

1988 Dahlgren System 300 computer engraver, converted in 1997 to the then-current Xenetech controller and software. Both companies now out of business, the Xenetech software runs in windows 95 or 98, and has a 16-bit ISA interface card that needs a 1998-vintage PC. The setup came with a very ill PC. I was able to resurrect Windows 98 and get it working, but no serial number for the controller software so I have one month to get it functional. After one month I'd have to scrub and re-install Windows.

Engraver uses a spring-return pneumatic cylinder for Z-axis, so needs a compressed air supply to operate.

So the decision was made to retire all the original computer system and install current stepper motors, a proper stepper motor Z-axis, and build a new controller running GRBL. Keeping the original spindle motor and speed control, 90 VDC variable speed at 20,000 RPM max. Uses 1/4" cutters, and it came with 30+ cutters from 0.010" to 0.125" diameter.

This thing is built like a tank. Baseplate is a 34"x34"x1/2" solid chunk of aluminum plate, 24" x 12" X-Y travel, Z quill travel 0.50" with 4.5" vertical adjustment. Without the controller it weighs about 100 lbs.

First step was to tear it all down and clean, next step will be to fabricate bracketry to add limit switches.

Leftover bits:

Xenetech stepper driver controller

Xenetech operator pendant

Windows 98 PC, Pentium 233, 64MB RAM, 6GB hard drive, DVD drive, 56K modem, 10/100 network card

Soundblaster Vibra 16 ISA card

Xenetech ISA controller card

Xenetech communication cables between PC and controller

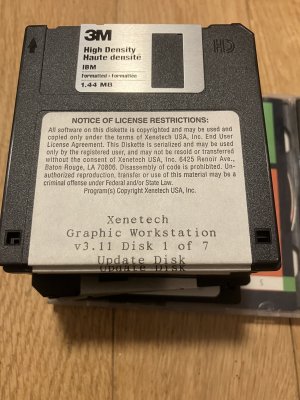

Xenetech software on 3-1/2" floppies and CD-ROM

Anyone need any of this?

1988 Dahlgren System 300 computer engraver, converted in 1997 to the then-current Xenetech controller and software. Both companies now out of business, the Xenetech software runs in windows 95 or 98, and has a 16-bit ISA interface card that needs a 1998-vintage PC. The setup came with a very ill PC. I was able to resurrect Windows 98 and get it working, but no serial number for the controller software so I have one month to get it functional. After one month I'd have to scrub and re-install Windows.

Engraver uses a spring-return pneumatic cylinder for Z-axis, so needs a compressed air supply to operate.

So the decision was made to retire all the original computer system and install current stepper motors, a proper stepper motor Z-axis, and build a new controller running GRBL. Keeping the original spindle motor and speed control, 90 VDC variable speed at 20,000 RPM max. Uses 1/4" cutters, and it came with 30+ cutters from 0.010" to 0.125" diameter.

This thing is built like a tank. Baseplate is a 34"x34"x1/2" solid chunk of aluminum plate, 24" x 12" X-Y travel, Z quill travel 0.50" with 4.5" vertical adjustment. Without the controller it weighs about 100 lbs.

First step was to tear it all down and clean, next step will be to fabricate bracketry to add limit switches.

Leftover bits:

Xenetech stepper driver controller

Xenetech operator pendant

Windows 98 PC, Pentium 233, 64MB RAM, 6GB hard drive, DVD drive, 56K modem, 10/100 network card

Soundblaster Vibra 16 ISA card

Xenetech ISA controller card

Xenetech communication cables between PC and controller

Xenetech software on 3-1/2" floppies and CD-ROM

Anyone need any of this?

Attachments

Last edited: