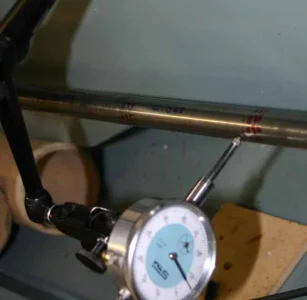

Does anyone have leads of an outfit that could do straightening of my lathe power shaft? I'm now suspecting that might be the root of my issue. Its 1372mm long x 19mm diameter with a 5mm keyway slot up until a couple inches of the tailstock end. With both ends constrained in the HS drive socket & TS bearing & just rotating by hand with a dial, I'm measuring max run-out from headstock to tailstock at roughly 6" increments like: 0.015", 0.025", 0.048", 0.050", 0.052", 0.050", 0.045", 0.027", 0.017".

I've watched some shaft straightening vids like Keith Fenner, most use OA torch, some also cooling in a dedicated test jig. And what looks like some seasoned technique. None of which I have. I've Google'd some driveline places but not sure if they do this sort of thing, cost, lasting results etc.? I'll call Modern Tool to see if they have leads, they must see this issue too. But just wondering if anyone has some prior +/- experience with remedies?

I've watched some shaft straightening vids like Keith Fenner, most use OA torch, some also cooling in a dedicated test jig. And what looks like some seasoned technique. None of which I have. I've Google'd some driveline places but not sure if they do this sort of thing, cost, lasting results etc.? I'll call Modern Tool to see if they have leads, they must see this issue too. But just wondering if anyone has some prior +/- experience with remedies?